PFC Model Formulation

PFC is classified as a distinct-element code because it allows finite displacements and rotations of discrete particles (including complete detachment), recognizes new contacts automatically as the calculation progresses and solves the time evolution of this discrete system using an explicit dynamic solution to Newton’s laws of motion. Refer to the section “PFC Overview” for a general introduction to the Distinct-Element Method (DEM) and PFC. The present section provides an overview of the DEM formulation as implemented in PFC prior to delving into an overview of PFC Model Components, followed by discussion of Cycling and, finally, Energy and Dissipation Mechanisms in PFC.

Overview

A PFC model simulates the physical interactions of many particles. Each particle in a PFC model is denoted as a body to clarify the fact that it is not a point mass; a body is a discrete, rigid body with finite extent and a well-defined surface. The PFC model is populated with bodies, pieces and contacts. There are three types of bodies: balls, clumps and walls. Each body is composed of one or more pieces. A ball consists of one piece, which is the ball itself; a clump is made of one or more pebbles; and a wall is comprised of one or more facets. Contacts are pair-wise interactions between pieces that are created and destroyed as the simulation proceeds. Contacts hold forces and moments that are applied to the contacting bodies. Those forces/moments are calculated via interaction laws termed contact models. Balls, clumps, walls and contacts are referred to as the PFC model components because they constitute the physical components of a PFC model. The PFC model state refers to the current spatial configuration and state (e.g., velocities, forces, moments, etc.) of the model components at a specific time during a simulation.

Being an explicit, timestepping formulation, the model state is advanced in time by a series of calculation cycles, or cycles, as the simulation progresses. Custom criteria may be specified to terminate a series of cycles based on the current model state. A rich set of emergent behaviors, resulting from the interactions of many bodies, may be observed and queried while cycling toward a terminal model state; this set of behaviors is one of the defining characteristics of DEM simulations.

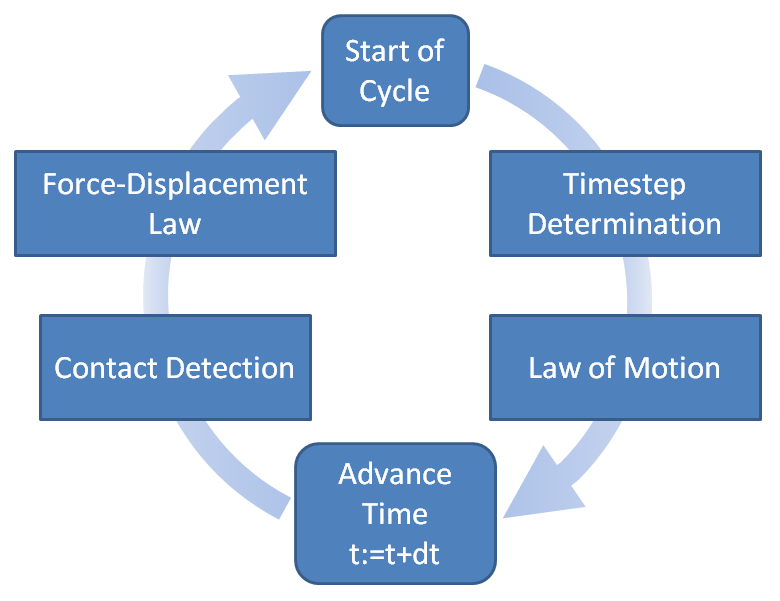

The cycle sequence is the sequence of operations that are executed during a single PFC cycle. The figure below depicts a simplified version of the cycle sequence as implemented in PFC. These operations include:

- Timestep Determination - The DEM method requires a valid, finite timestep to ensure the numerical stability of the model and that all contacts are created between pieces prior to the point that forces/moments develop between interacting bodies.

- Law of Motion - The position and velocity of each body/piece is updated according to Newton’s laws of motion using the current timestep and the forces/moments calculated during the previous cycle.

- Advance Time - The model time is advanced by adding the current timestep to the previous model time.

- Contact Detection - Contacts are dynamically created/deleted based on the current piece positions.

- Force-Displacement Law - The forces/moments developing at each contact are updated by the appropriate contact model using the current state of the pieces.

In order to elucidate the dynamics of a PFC model, one may need to track the energy balance. Energy dissipation may occur in contact interaction laws (e.g., via frictional sliding, viscous damping, plasticity, etc.) or as a result of the damping mechanism termed local damping. Local damping may be used to accelerate convergence to a steady-state solution. The energy balance, including energy dissipation mechanisms, is discussed in the Energy and Dissipation Mechanisms in PFC section.

In Detail

| Was this helpful? ... | FLAC3D © 2019, Itasca | Updated: Feb 25, 2024 |