WIPP Model: Cylindrical Cavity

Note

To view this project in 3DEC, use the menu command . Choose “CreepMaterialModels/CylindricalCavityWIPP” and select “CylindricalCavityWIPP.prj” to load. The project’s main data files are shown at the end of this example.

The WIPP-reference creep model in 3DEC is used to solve the problem of radial creep of an infinitely long, thick-walled cylinder subjected to a pressure on its outer surface. The analytical steady-state solution, assuming that creep is defined by a single-component power law, is provided in Power Model: Cylindrical Cavity. The WIPP model can be converted to a power law formulation by using only the secondary creep-strain component. This is achieved by setting the WIPP properties a_wipp and b_wipp to zero. The WIPP model is then reduced to the form

where \(A = D \exp(-Q/RT)\).

For this problem, \(Q\) = 12,000 cal/mol, \(R\) = 1.987 cal/mol K, \(T\) = 300° K, \(D\) = 5.5299 × 10-17 (or \(A\) = 1 × 10-25 Pa-3 yr-1), and \(n\) = 3. The elastic properties of the material are \(E\) = 820 MPa and \(\nu\) = 0.3636.

The model uses the same 3DEC grid and the same boundary conditions as as those described in Power Model: Cylindrical Cavity.

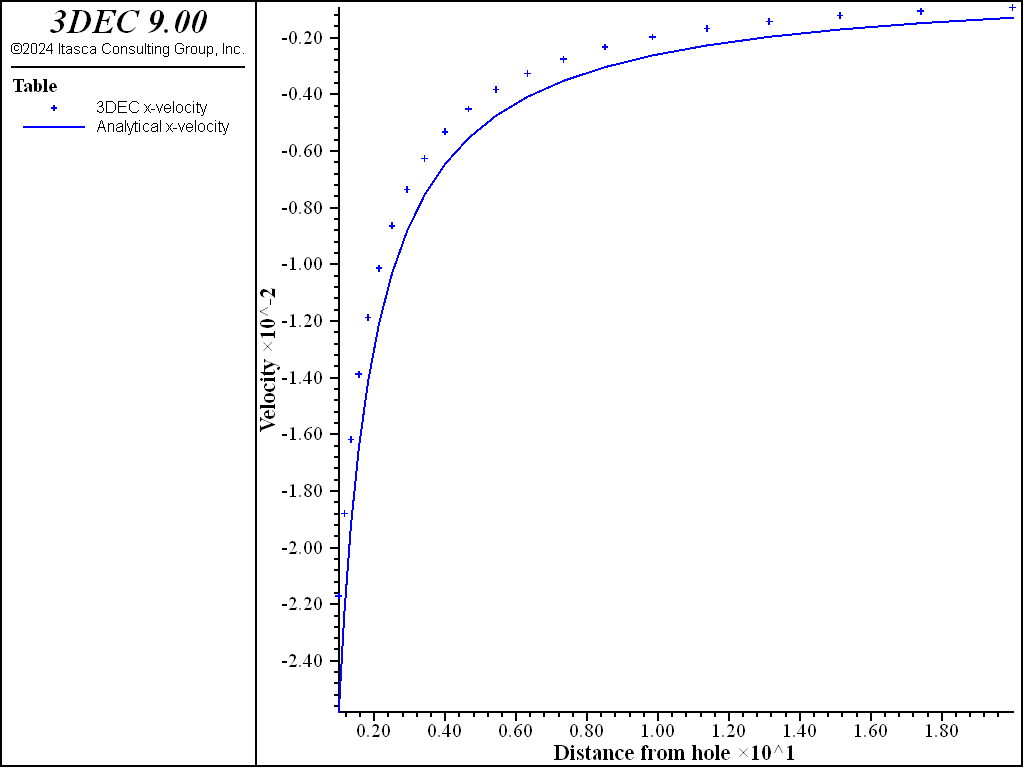

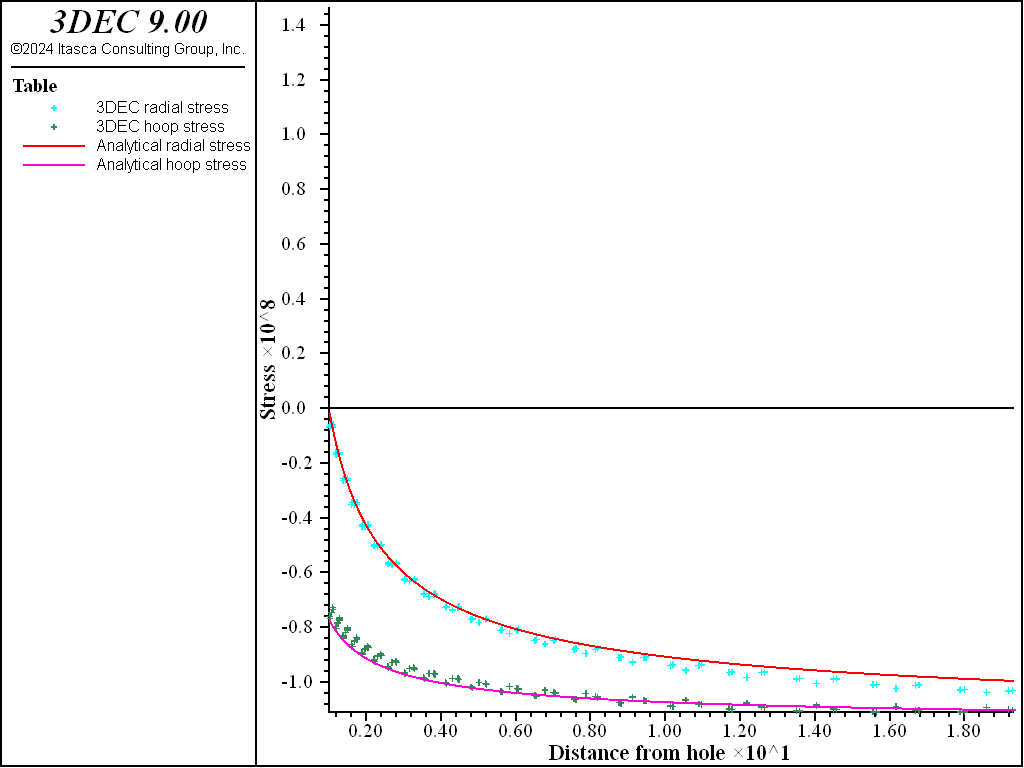

The results of this example are summarized in Figure 1 and Figure 2. Figure 1 compares the analytical solution for the radial velocity in the steady-state condition with the 3DEC results. Figure 2 shows the comparison of radial and hoop stresses. The agreement between results is similar to that for the power law test in Power Model: Cylindrical Cavity.

Figure 1: Comparison of radial velocity at steady state—3DEC WIPP model (symbol), analytical (line) versus radial distance.

Figure 2: Comparison of radial and hoop stress at steady state—3DEC WIPP model radial stress (symbol), analytical radial stress (line), 3DEC WIPP model hoop stress (symbol), analytical hoop stress (line) versus radial distance.

Data File

CylindricalCavityWIPP.dat

;------------------------------------------------------------

; cylindrical cavity -- power law model

;-------------------------------------------------------------------

model new

fish automatic-create off

model title "Power-Law Creep Model --- Cylindrical Cavity"

model configure creep

model large-strain off

block tolerance 0.001

;

program call 'cylinder.fis'

[r_inner = 1.0]

[r_outer = 20.0]

[nr = 20]

[nd = 1]

[nc = 10]

[ratio = 1.1]

[length = 0.1]

[cylinder]

block join on

;block zone generate center 0 0 0 edgelength-center 0.1 edgelength-dist 2.5 distance 20

block zone generate hexahedra

block zone cmodel wipp

; Properties and stresses in Pascal units (not MPa)

block zone property density 2700 bulk 1e9 shear 3e8

block zone property constant-gas 1.987 activation-energy 12e3 ...

exponent 3 constant-d 5.5299e-17

block zone property constant-a 0 constant-b 0 creep-rate-critical 5.39e-8 ...

temperature 300

;

; apply stress first!

block face apply stress -100e6 -100e6 -100e6 0 0 0 ...

range cylinder end-1 0 0 0 end-2 0 0 -1 radius 19 21

block gridpoint apply velocity-x 0 range position-x 0

block gridpoint apply velocity-y 0 range position-y 0

block gridpoint apply velocity-z 0 range position-z -1 0

block zone initialize stress xx -100e6 yy -100e6 zz -100e6

;

model creep active off

model solve ratio 1e-7

model save 'cyl_1'

model history mechanical unbalanced-maximum

block history velocity-x position 1 0 0

block history velocity-x position 20 0 0

block history displacement-x position 1 0 0

block history displacement-x position 20 0 0

block history stress-xx position 1 0 0

block history stress-yy position 1 0 0

block history stress-zz position 1 0 0

model history creep time-total

model history timestep

;

block gridpoint initialize displacement (0,0,0)

block gridpoint initialize velocity (0,0,0)

model creep active on

model creep timestep starting 1.0e-6

model creep timestep minimum 1.0e-6

model creep timestep maximum 0.1

model solve time-total 200

model save 'cyl_2'

; compare analytic solution......

program call 'solution.fis' suppress

table '1' label '3DEC x-velocity'

table '11' label 'Analytical x-velocity'

table '2' label '3DEC radial stress'

table '12' label 'Analytical radial stress'

table '3' label '3DEC hoop stress'

table '13' label 'Analytical hoop stress'

table '4' label '3DEC out-of-plane stress'

table '14' label 'Analytical out-of-plane stress'

model save 'cylindrical-cavity-wipp'

program return

| Was this helpful? ... | Itasca Software © 2024, Itasca | Updated: Apr 02, 2024 |