FLAC3D Modeling • Problem Solving with FLAC3D

Boundary Conditions

The boundary conditions in a numerical model consist of the values of field variables (e.g., stress and displacement) that are prescribed at the boundary of the numerical grid. Boundaries are of two categories: real and artificial. Real boundaries exist in the physical object being modeled (e.g., a tunnel surface or the ground surface). Artificial boundaries do not exist in reality, but they must be introduced in order to enclose the chosen number of zones. The conditions that can be imposed on each type are similar; these conditions are discussed first. Then (in Artificial Boundaries) some suggestions concerning the location and choice of artificial boundaries and the effect they have on the solution are made.

Mechanical conditions that can be applied at boundaries are of two main types: prescribed displacement or prescribed stress. A free surface is a special case of the prescribed-stress boundary. The two types of mechanical conditions are described in Stress Boundary and Displacement Boundary.

To view this project, use the menu command .

Stress Boundary

By default, the boundaries of a FLAC3D grid are free of stress and any constraint. Forces or

stresses may be applied to any boundary, or part of a boundary, by means of the

zone face apply command. Individual components of the stress tensor are specified with

the stress-xx, etc., keywords. For example, the commands

zone face apply stress-zz -1e5 range position-z 0

zone face apply stress-xz -5e4 range position-z 0

apply the given \(\sigma_{zz}\) and \(σ_{xz}\) components of a stress tensor to all boundary zone faces with centroids that fall within the range -0.1 ≤ \(z\) ≤ 0.1. All other stress components are zero.

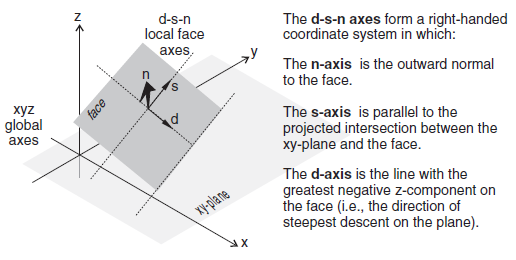

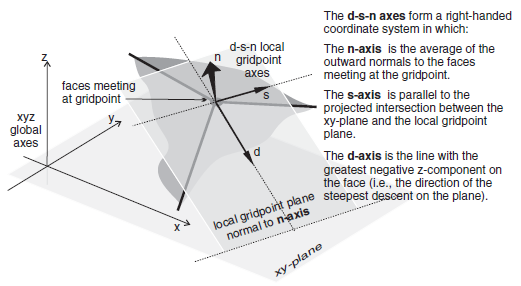

Stress can be applied either in the global model \(x\),\(y\),\(z\)-directions, or in directions normal and tangential to the local boundary face. The keyword stress-normal applies a normal stress to a face, while keywords stress-dip and stress-strike apply shear stresses to the face. stress-dip is the stress component applied in the dip direction of the local face, and stress-strike is the stress component applied in the strike direction. The orientation of the local face axes is illustrated in the next figure. Note that global (\(x\),\(y\),\(z\))-axes stresses and local (\(d\),\(s\),\(n\))-axes stresses cannot both be applied to the same face.

There are several things to note about this use of zone face apply command. First, only

those faces inside the range defined by range will be affected by the

zone face apply command, and as with all face selection geometric range elements, will

select by the location of the face centroid. Second, compressive stresses have a negative

sign, in accordance with the general sign convention for internal

stresses in FLAC3D. Finally, FLAC3D actually applies the stress components as forces, or

tractions, which result from a stress tensor acting on the given boundary plane; the tractions

are computed whenever a model solve command is issued, and again every tenth step in

large-strain mode.

Figure 1: Local face axes defined by (d) dip direction, (s) strike direction, and (n) normal direction.

Individual forces can also be applied to the grid by using the zone gridpoint fix command

and the force-applied-x, force-applied-y, and force-applied-z keywords,

which specify the \(x\)-, \(y\)-, and \(z\)-components of an applied force vector (all forces may be

specified at once using force-applied v). In this case, no account is taken of

the boundary face area; the specified forces are simply applied to the given gridpoints.

The applied forces, or tractions calculated from applied stresses, can be viewed with the Zone Vector plot item. It is necessary to perform a model step 0 first in order to

calculate the applied forces for viewing. For example, a stress boundary condition is applied

normal to a boundary plane that has a dip angle of 60° and dip direction of 270°. Cut and paste

the commands shown in the next example into a data file.

Name of example: Applying a normal stress to a dipping boundary

model new

zone create brick size (4,4,4) point 0 (0,0,0) point 1 (4,0,0) ...

point 2 (0,4,0) point 3 (2,0,3.464)

zone cmodel assign elastic

zone property bulk 1e8 shear .3e8

zone face apply stress-normal -1e6 ...

range plane dip 60 dip-direction 270 origin 0.1,0,0 above

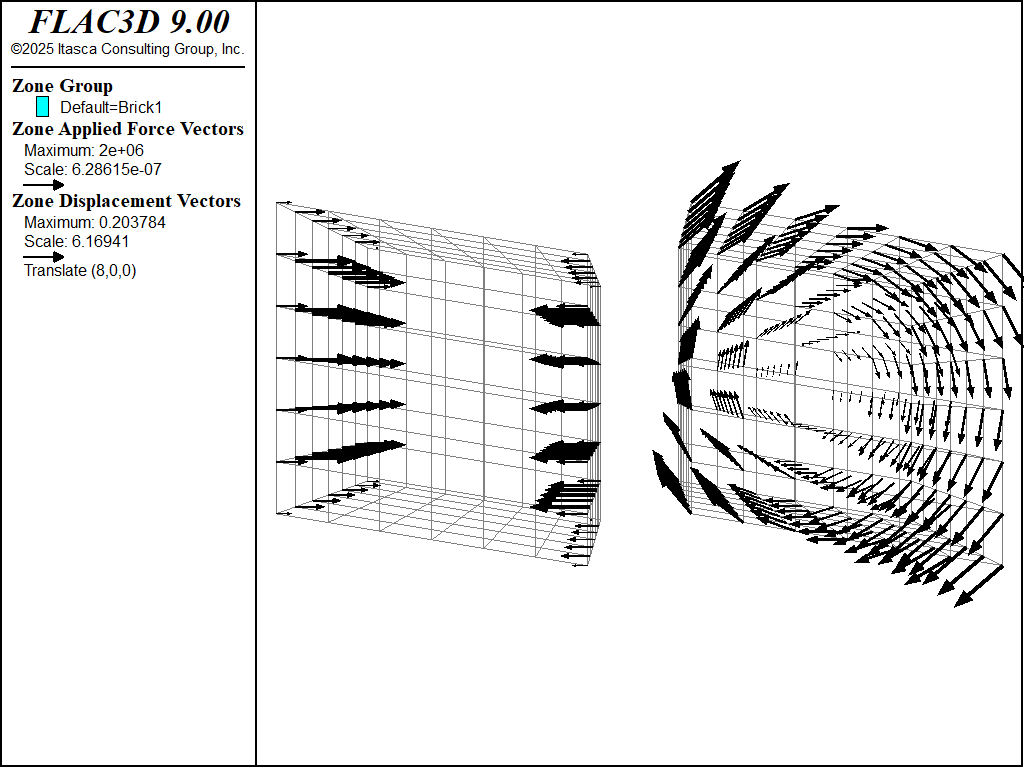

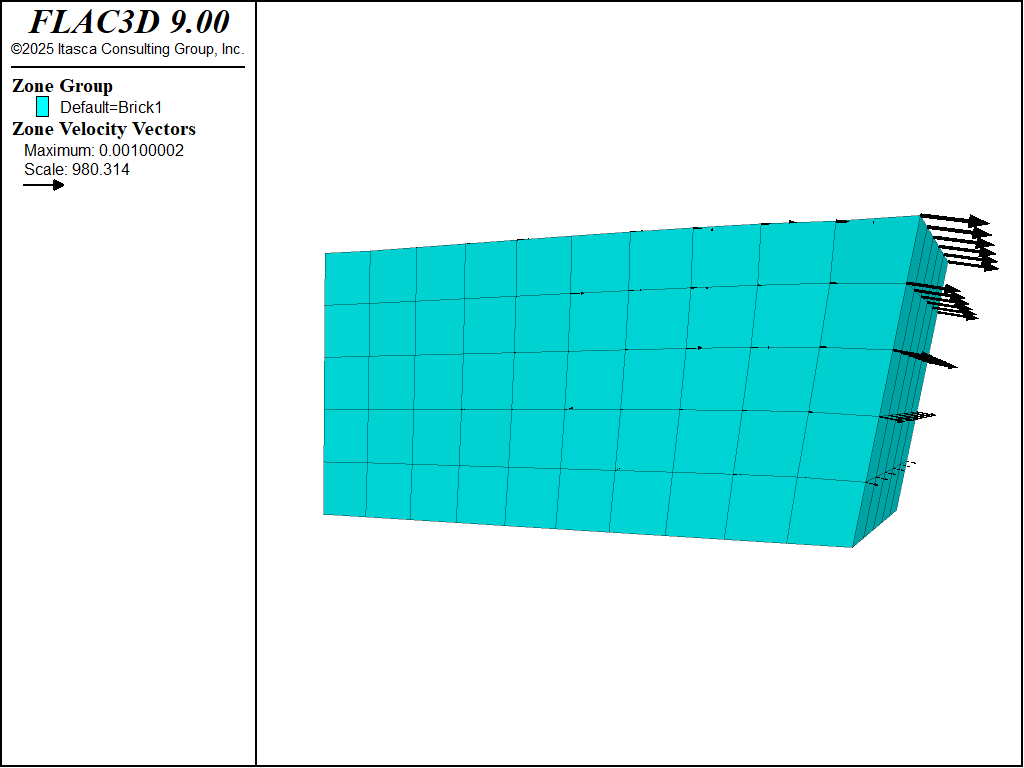

The normal stress of -1 × 106 is applied to a boundary plane falling within the range defined by a plane with a dip direction of 270°, a dip angle of 60°, and above the position \(x\) = 0.1, \(y\) = 0, \(z\) = 0. The resulting applied forces can be seen by plotting a “Zone->Vectors” plot item, and setting the “Applied Force” option on the “Value” attribute.

Note that by using the zone face skin command, the desired boundary can be identified

easily without the need to mathematically describe the plane, as seen below:

model new

model large-strain off

zone create brick size (4,4,4) point 0 (0,0,0) point 1 (4,0,0) ...

point 2 (0,4,0) point 3 (2,0,3.464)

zone face skin

zone cmodel assign elastic

zone property bulk 1e8 shear .3e8

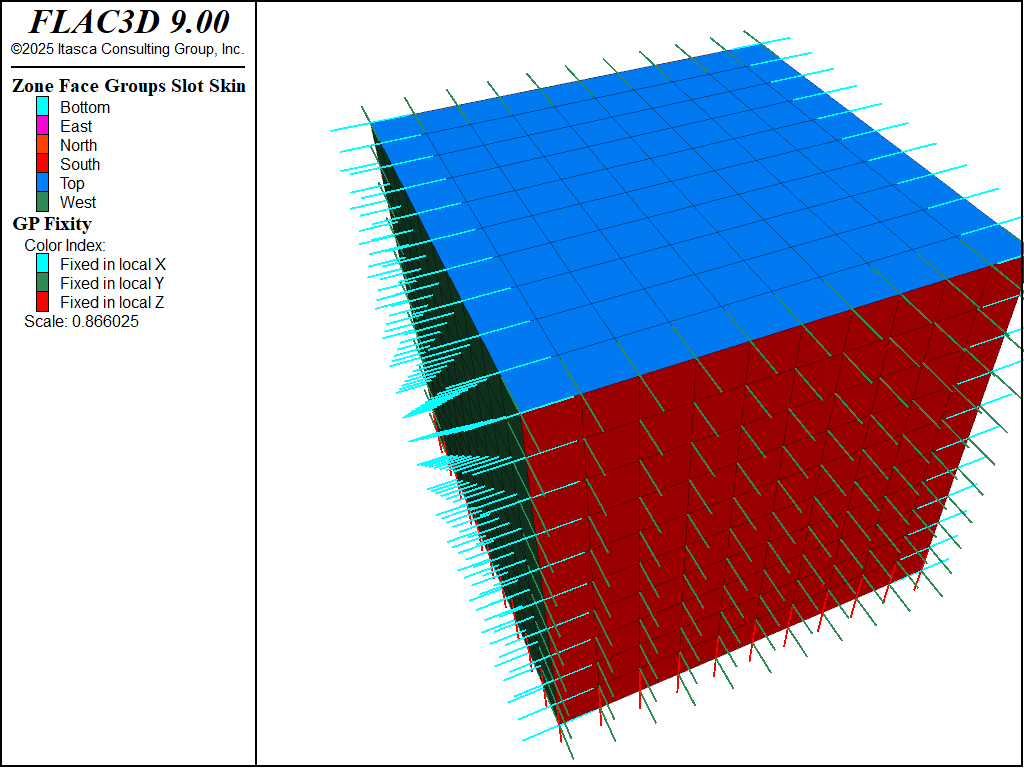

The plot below shows the forces applied to the grid as calculated from the normal stress and the boundary face areas. Note that the size of the force vectors is a function of the face areas over which the stress is applied.

Figure 2: Applied forces resulting from zone face apply stress-normal.

Applied Stress Gradients

The zone face apply command may take the optional keyword gradient, which allows

the applied stresses or forces to vary linearly over the specified range. The parameter

following gradient, v, specifies the \(x\)-, \(y\)-, and \(z\)-variation, respectively,

for the stress- or force-component. The value varies linearly with distance from the global

coordinate origin at (\(x\) = 0, \(y\) = 0, \(z\) = 0):

in which \(S^{(o)}\) is the value at the global coordinate origin at (\(x\) = 0, \(y\) = 0, \(z\) = 0), and \(g_x\), \(g_y\), and \(g_z\) specify the variation of the value in the \(x\)-, \(y\)-, and \(z\)-directions.

The operation of this feature is best explained by an example:

zone face apply stress-xx -10e6 gradient (0,0,1e5) range position-z -100 0

The equation for the \(z\)-variation in stress-component \(\sigma_{xx}\) is

The \(\sigma_{xx}\)-stress at the origin (\(x\) = 0, \(y\) = 0, \(z\) = 0) is \(\sigma_{xx}\) = -10 × 106; at \(z\) = -100, it is -20 × 106. At points in between, the stress is linearly scaled to the relative \(z\)-distance from the origin.

Another option is to use the vary keyword, which may be more familiar from FLAC. See Value Modifiers (add, multiply, gradient, & vary keywords) for further discussion of both options.

Typically, applied stress gradients are used to reproduce the effects of increasing stress with

depth caused by gravity. It is important to make sure that the applied gradient is compatible

with the stress gradient specified with the zone initialize-stresses command. See

Initial Conditions for further comments on stress gradients.

Changing Boundary Stress

It may be necessary to alter the values of applied stresses during the course of a FLAC3D

simulation. For example, the load on a footing may change. To effect a sudden change in an

existing applied stress or load, a new zone face apply command is given, with the range

and stress component given exactly as in the original command, but with a changed value or

variation. In this case, FLAC3D will detect a conflict in the apply condition already present

and remove it. New values will replace existing values for any overlapping

zone face apply commands. It may be necessary to first remove boundary conditions (with

zone face apply-remove) before updating a boundary stress.

In many instances, it may be necessary to change a boundary stress gradually. This is often

required to minimize the shock to a sensitive system, especially if “path-dependence” of the

solution is important (see Localization, Physical Instability and Path-Dependence). The zone face apply command includes options to make gradual application (or removal) of boundary conditions simple and straightforward. For example, to increase the applied stress incrementally while maintaining quasi-equilibrium, you can use the ramp option to the servo keyword:

zone face apply stress-xx -1e5 servo ramp range group 'East' position-z 0,2

Apply changing stress boundary with a FISH function

The servo keyword and its various options is only one way to change the value of an applied boundary over time. Either FISH or tables can be used to add a multiplier to the value. Each step, the table is queried or the FISH function is called, and the value of the applied boundary will be multiplied by the return. A return of 1.0 will therefore have no effect, and a return value of 0.0 will effectively remove the boundary (in the case of stress boundaries). The following is a simple example of using a short FISH function to vary the stress applied sinusoidally.

fish define apply

apply = math.sin(dynamic.time.total*10)

end

zone face apply stress-xx -1e5 fish apply range group 'East' position-z 0,2

Apply changing stress boundary with table data

The following example creates a simple table that is used to gradually ramp the stress boundary up from nothing. Note that for a table multiplier, you must specify the time value to use as the \(x\) lookup. In this case, we specify dynamic time. By default, a table multiplier will use the current total step number as the \(x\) lookup value.

table 'ramp' add (0,0) (1,1)

zone face apply stress-xx -1e5 table 'ramp' time dynamic ...

range group 'East' position-z 0,2

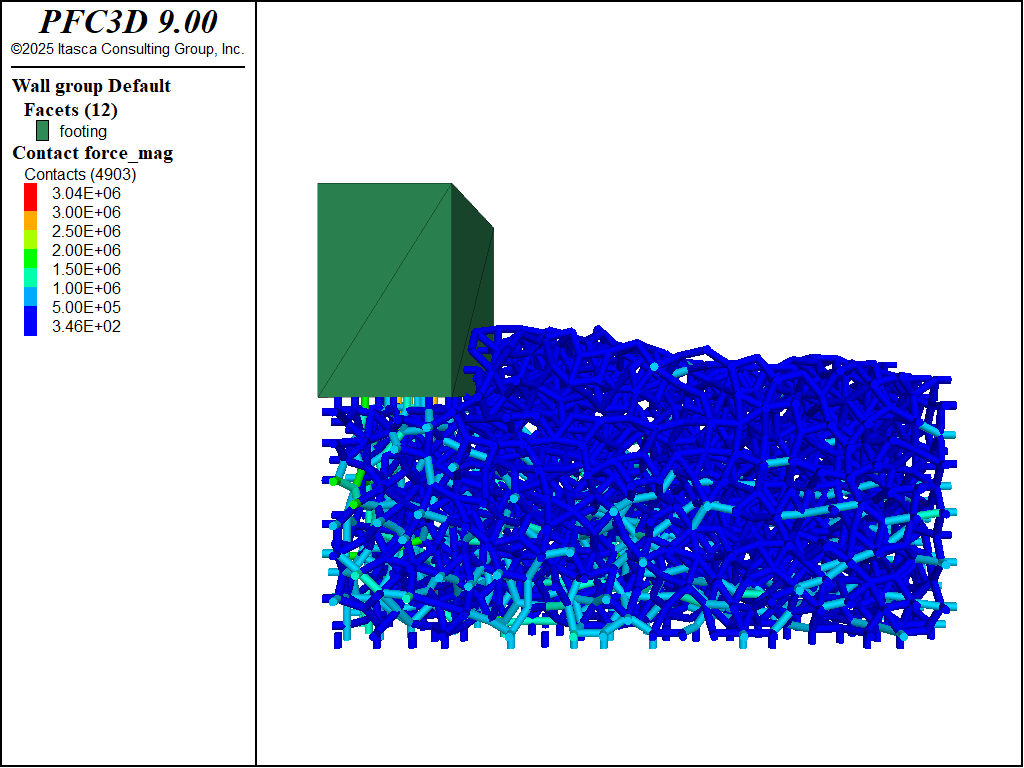

Gradual excavation of a circular tunnel

Because FLAC3D uses physics to inform the path it takes to static convergence, sudden changes

to the model can have quasi-inertial effects that may artificially exaggerate damage in the

area. One way to mitigate this is to gradually excavate regions, so that the effect of zone

removal is less sudden. The zone relax excavate command was created for this purpose.

This command is a zone-based apply condition that gradually reduces the stress, stiffness, and

density of the zones in the range until they have effect on the model and are then set to the

null constitutive model. Previous sentence is missing a word, should there be a “no” in

front of “effect?

By default, zone relax uses a servo to automatically maintain quasi-equilibrium, however

the command has any number of options for controlling the exact method of reducing the influence

of zones tagged for excavation.

The following example creates a simple circular tunnel. This tunnel is both excavated instantly

and gradually via zone relax excavate.

model new

model large-strain off

; Create zones

zone create radial-cylinder point 0 0 0 0 point 1 add 18 0 0 ...

point 2 add 0 8 0 point 3 add 0 0 18 ...

dimension 1.75 1.75 1.75 1.75 ratio 1.0 .83 1.0 1.2 ...

size 6 6 6 15 fill group 'exc'

zone create radial-cylinder point 0 0 8 0 point 1 add 18 0 0 ...

point 2 add 0 8 0 point 3 add 0 0 18 ...

dimension 1.75 1.75 1.75 1.75 ratio 1.0 1.2 1.0 1.2 ...

size 6 6 6 15 fill

zone face skin

; Assign constitutive models and properties

zone cmodel assign mohr-coulomb

zone property bulk 33.33e9 shear 25e9 friction 45 cohesion 15e6 tension 5e6

; Assign Boundary Conditions

zone face apply velocity-normal 0 range group 'West' or 'East'

zone face apply velocity-normal 0 range group 'South' or 'North'

zone face apply velocity-normal 0 range group 'Bottom' or 'Top'

; Initial Conditions

zone initialize stress xx -65e6 yy -65e6 zz -65e6

model solve

model save 'initial'

; instantaneous excavation

zone delete range group 'exc'

model solve

model save 'instant'

; gradual excavation

model restore 'initial'

zone relax excavate range group 'exc'

model solve

model save 'relax'

Note that the total number of steps taken to reach equilibrium is actually a little lower when relaxation is used. This is not uncommon.

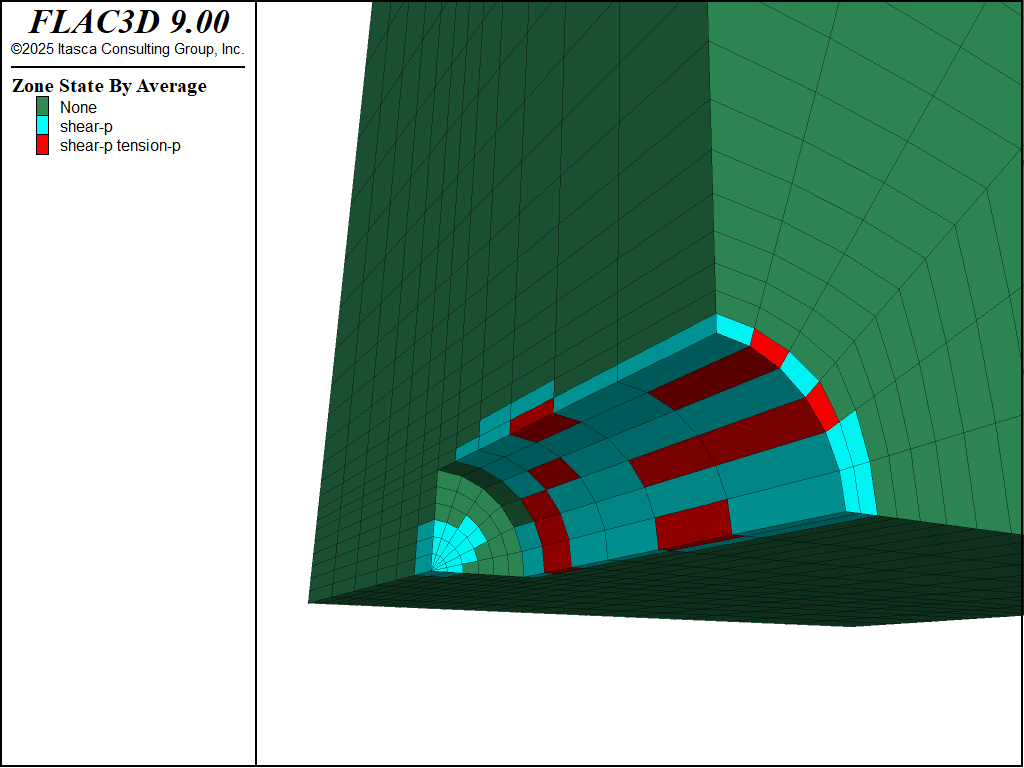

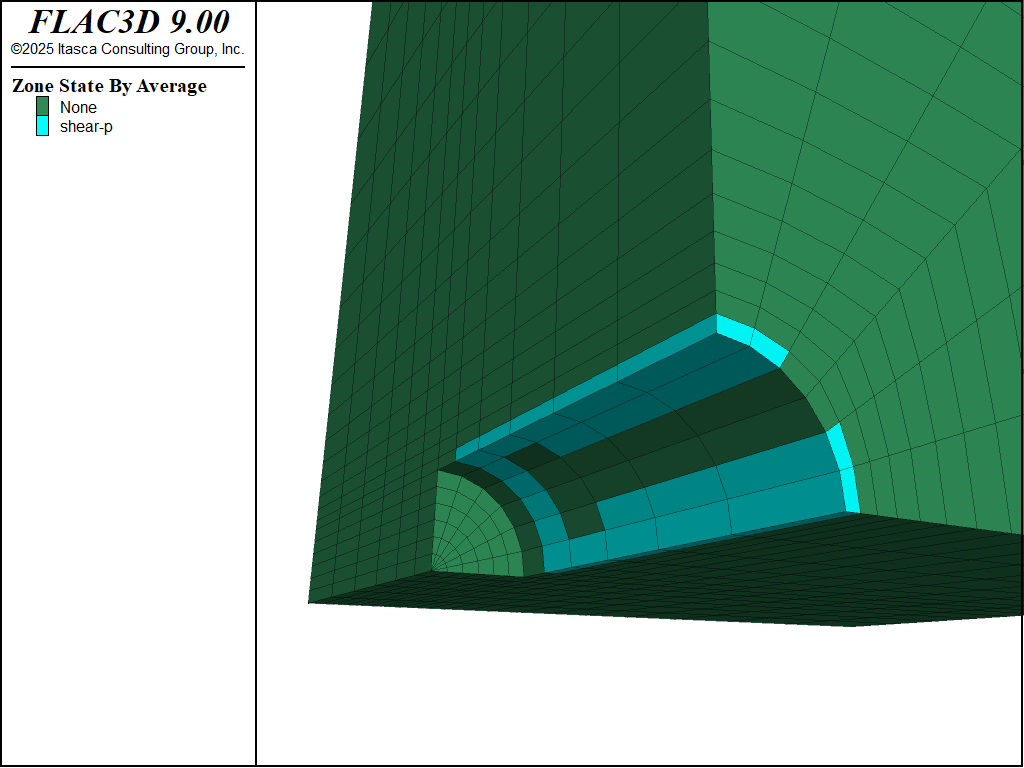

An examination of the state flags for the zones surrounding the excavation shows that the relaxed version not only shows less damage, but is entirely lacking in tensile failure indicators.

Figure 3: Plasticity state for instantaneous excavation of tunnel.

Figure 4: Plasticity state for relaxed excavation of tunnel.

Cautions and Advice

In this section, some miscellaneous difficulties with stress boundaries are described.

With FLAC3D, it is possible to apply stresses to the boundary of a body that has no displacement constraints (unlike many finite-element programs, which require some constraints). The body will react in exactly the same way as a real body would (i.e., if the boundary stresses are not in equilibrium, then the whole body will start moving). The following data file illustrates the effect.

Spin when grid is not in equilibrium

model new

model large-strain off

zone create brick size 6,6,6 point 1 (6,0,-1)

zone cmodel assign elastic

zone property bulk 8e9 shear 5e9

zone face apply stress-xx -2e6 range position-x 0

zone face apply stress-xx -2e6 range position-x 6

model step 500

The plots produced from this example are given in the following figure. The applied \(\sigma_{xx}\) stress causes horizontal forces to act on the body. Because the body is tilted, these forces give rise to a moment that causes the body to spin.

Figure 5: Applied horizontal forces and rotational displacement induced on tilted body.

A similar, but more subtle, effect arises when material is excavated from a body that is supported by a stress boundary condition: the body is initially in equilibrium under gravity, but the removal of material reduces the weight. The whole body then starts moving upward, as demonstrated by the following data file.

Uplift when material is removed

model new

model large-strain off

; Create zones

zone create brick size 5,5,5

zone face skin

; Assign model and properties

zone cmodel assign elastic

zone property bulk 8e9 shear 5e9 density 1000

; Boundary Conditions

zone face apply velocity-normal 0 range group 'West' or 'East'

zone face apply velocity-normal 0 range group 'North' or 'South'

zone face apply stress-normal -5e4 range group 'Bottom'

; Initial Conditions

model gravity 10

zone initialize-stresses

model solve ; Starts at equilibrium

zone cmodel assign null range position (1,1,3) (4,4,5)

model step 100 ; body no longer in equilibrium

The uplift is shown in the next figure. The difficulty encountered in running this data file can be eliminated by fixing the bottom boundary, rather than supporting it with stresses. The Artificial Boundaries section contains some information relating to the location of such artificial boundaries.

Figure 6: Uplift of model when material is removed.

Displacement Boundary

Displacements cannot be controlled directly in FLAC3D; in fact, they play no part in the

calculation process. In order to apply a given displacement to a boundary, it is necessary to

prescribe the boundary’s velocity for a given number of steps. If the desired displacement is

\(D\), a velocity \(V\) over \(N\) steps (where \(N = D/V\)) may be applied. In

practice, \(V\) should be kept small and \(N\) large, in order to minimize shocks to the

system being modeled. The zone face apply command or the zone gridpoint fix and

zone gridpoint initialize commands can be used to specify the velocities; gradients may

also be specified.

Local System and Applied Velocities

Applied velocity conditions always refer to gridpoints, though they may be applied via zone-face

commands (e.g., zone face apply velocity-local) or zone-gridpoint commands. When

zone-face commands are used, all gridpoints connected to selected faces are selected.

Velocities can be applied in terms of the \(x\),\(y\),\(z\)-global axes (i.e., with keywords velocity-x, velocity-y, or velocity-z) or in terms of a local axes (with keywords velocity-dip, velocity-strike, or velocity-normal). All local or global velocity components may be supplied as a vector in one command (with velocity-local v, or velocity v, respectively). The local axes are defined by the normal vector at each gridpoint, using the convention in the figure below:

Figure 7: Local gridpoint axes defined by (d) dip direction, (s) strike direction, and (n) normal direction.

Each gridpoint has its own local coordinate system, which can be specified with the

zone gridpoint system command. The zone face apply logic will over-write those

values if necessary to apply the conditions requested. It will also automatically attempt to

rotate and select appropriate local degrees-of-freedom to allow multiple velocity constraints to

be present in the same gridpoint. If this is not possible, then a previous apply condition will

be removed to make way for the new one. This means that it is not necessary to work out a

compatible local system on sloped or irregular boundaries ahead of time. For example, it is

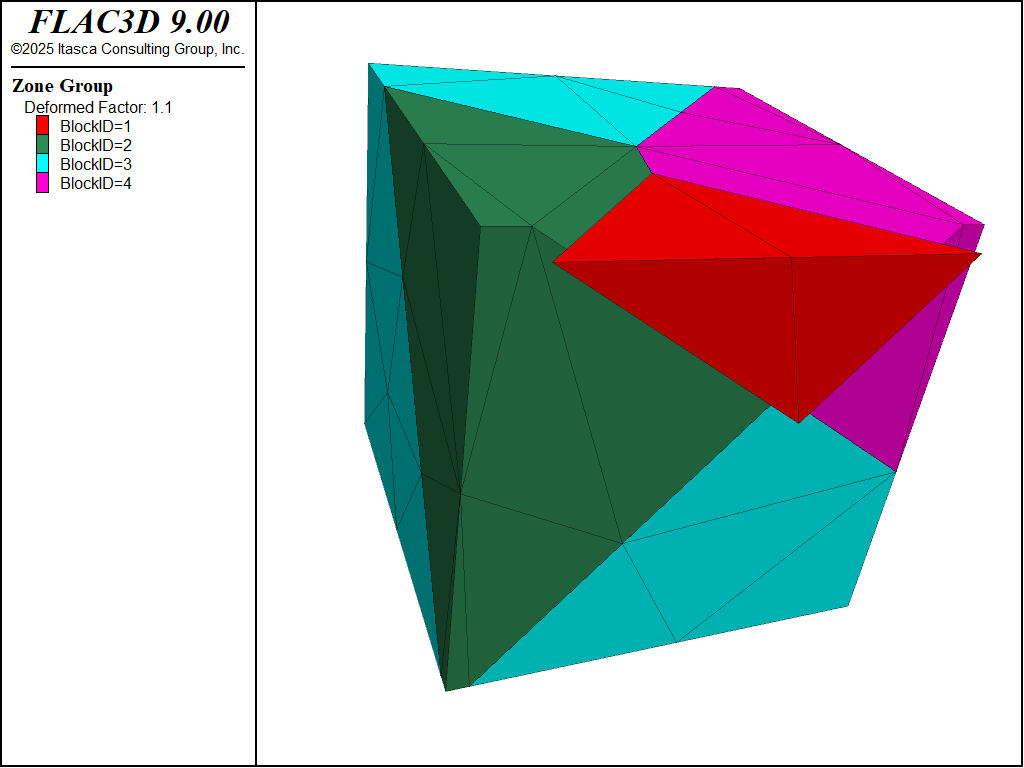

possible to apply roller boundaries to a wedge-shaped block in a single command:

zone face apply velocity-normal 0 range group 'East' or 'Bottom'

plot 'Wedge' export bitmap filename 'Wedge.png'

model new

Figure 8: Gridpoint constraints on a wedge-shaped section.

Note that the normal direction was automatically selected on the sloped surface and multiple constraints on the toe were applied. The out of plane degree of freedom in the toe is still free.

Surface Corners and Velocity Boundaries

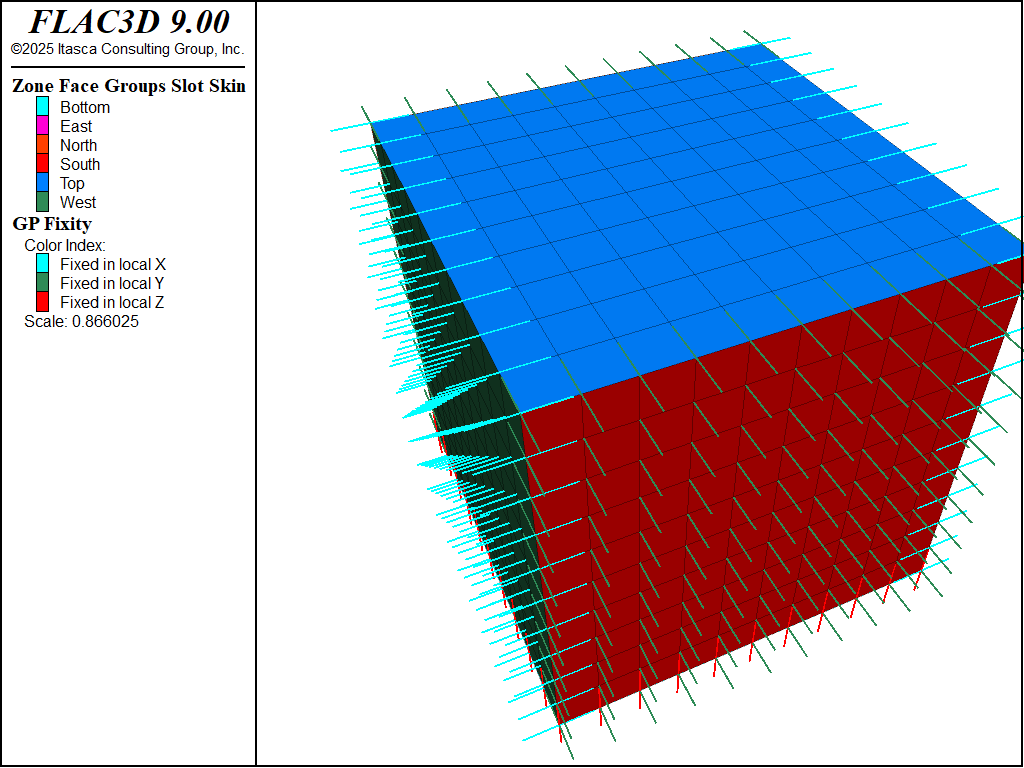

The gridpoint normal direction used is the average of the normal vectors of the faces included in that apply condition that meet at a gridpoint. This means that care must be taken to select faces that result in the desired normal vector, and commonly, multiple apply commands are necessary to prescribe multiple conditions on gridpoints along boundaries. For example, if one attempted to apply roller boundaries to five sides of a mode in one command with:

zone face apply velocity-normal 0 range group 'Top' not

plot 'Vel' export bitmap filename 'Vel1.png'

then the result can be seen in the following plot of gridpoint fixity. The corners of the model have been fixed at a diagonal, because that is the normal vector calculated using the average of all faces included in that apply that is connected to a gridpoint.

Figure 9: Velocity constraint directions from attempting to apply roller boundaries in a single command.

If the command were split into three, with the ‘East’ and ‘West’ done separately from the ‘North’ and ‘South’ and the ‘Bottom’, then the result is:

plot 'Vel' export bitmap filename 'Vel2.png'

model new

Figure 10: Velocity constraint directions when multiple apply commands are used.

This pattern is seen often in example problems in the FLAC3D documentation. Note that it is acceptable to combine ‘West’ and ‘East’ into one command because those surfaces do not share a boundary.

Velocity conditions can be applied at any orientation by using the local axes. A normal gridpoint direction can be specified arbitrarily for the local axes by using the system keyword; this will override the default normal direction.

Fix vs Apply

Another method of specifying velocities at gridpoints is to use the zone gridpoint fix

command. For example, the following commands are equivalent. Both commands apply a fixed

velocity of (1e-5,0,0) to all gridpoints connected to faces of group East.

In general, using the zone face apply command is preferred because the apply logic uses

the gridpoint local systems and fixity flags. Any values set there manually may be over-ridden

by a later apply condition. Also, the apply logic calculates local systems and attempts to

moderate between multiple constraints automatically. Note, however, that zone face apply

can currently only be performed on surface faces, where zone gridpoint fix can be done on

any gridpoints in the model.

Reaction Forces

When gridpoints are moved rigidly, the reaction forces at the gridpoints can be monitored using FISH. The sum of the reaction forces along a boundary may be obtained with a simple FISH function that adds up the values returned from the gp.force.unbal intrinsic over the desired range. (See Monitoring load on a zone (FLAC3D) in FISH Tutorial.)

Nonuniform Velocities

If nonuniform prescribed velocities are required, the gradient keyword may be used. For a more complicated velocity profile, or one that changes as the simulation proceeds, it will be necessary to write a FISH function. The next example demonstrates this for the model of a rotating retaining wall on the right-hand side of a block of soil.

Rotating retaining wall

model new

; Create zones

zone create brick size 10 5 5

zone face skin

; Constitutive model and properties

zone cmodel elastic

zone property shear 1e8 bulk 2e8

; FISH function

fish operator apply(gp,dum,rate)

local p = gp.pos(gp)

local x = rate * p->z / 5.0

local z = -rate * (p->x - 10.0) / 5.0

return vector(x,0,z)

end

; Boundary conditions

zone face apply velocity (0,0,0) range group 'West' or 'Bottom'

zone face apply velocity (1,1,1) fish-local apply(0,0,1e-3) range group 'East'

; Setup

model large-strain on

; Cycle

model step 1000

In this example, the fish-local keyword is used to adjust the velocities at every gridpoint during cycling. The FISH funcion apply is called once for each gridpoint each cycle. The first argument gp is the pointer to the gridpoint. In this case, the second argument is unused. The location of the gridpoint is used to calculate a velocity that in large strain, will cause the right-hand boundary to rotate. The velocity profile of the wall is adjusted as the geometry changes in large-strain mode. Note that the given velocity in this example is much too high for a realistic simulation; it is for demonstration purposes only.

Real Boundaries — Choosing the Right Type

It is sometimes difficult to know which type of boundary condition to apply to a particular surface of the body being modeled. For example, in modeling a laboratory triaxial test, should the load applied by the platen be regarded as a stress boundary, or should the platen be treated as a rigid displacement boundary? Of course, the whole testing machine, including the platen, could be modeled, but that might be very time-consuming. (Remember that FLAC3D takes a long time to converge if there is a large contrast in stiffnesses.) In general, if the object applying the load is very stiff compared with the sample (say, more than 20 times stiffer), then it may be treated as a rigid boundary. If it is soft compared with the sample (say, 20 times softer), then it may be modeled as a stress-controlled boundary. Clearly, a fluid pressure acting on the surface of a body is of the latter category. Footings on soil can often be represented as rigid boundaries that move with constant velocity for the purpose of finding the collapse load of the soil. This approach has another advantage—it is much easier to control the test and obtain a good load/displacement graph. It is well-known that stiff testing machines are more stable than soft testing machines.

Artificial Boundaries

Artificial boundaries fall into two categories: planes of symmetry and planes of truncation.

Symmetry Planes

Sometimes it is possible to take advantage of the fact that the geometry and loading in a system

are symmetrical about one or more planes. For example, if everything is symmetrical about a

vertical plane, then the horizontal displacements on that plane will be zero. Therefore, we can

make that plane a boundary and fix all gridpoints in the horizontal direction using the

zone face apply velocity-normal 0 command, with the range given as the boundary

plane. In the case considered, the \(y\)- and \(z\)-components of velocity on the vertical plane of

symmetry are not affected and should not be fixed. Similar considerations apply to other planes

of symmetry. Planes of symmetry can also be set along boundaries that lie at angles to the \(x\),\(y\),\(z\)-coordinate axes.

Boundary Truncation

When modeling infinite bodies (e.g., tunnels underground) or very large bodies, it may not be possible to cover the whole body with zones, due to constraints on memory and computer time. Artificial boundaries are placed sufficiently far away from the area of interest that the behavior in that area is not greatly affected. It helps to know how far away to place these boundaries, and what errors might be expected in the stresses and displacements computed for the area of interest.

Several points should be considered when selecting the location for artificial boundaries:

A fixed boundary causes both stresses and displacements to be underestimated, while a stress boundary does the opposite.

The two types of boundary condition “bracket” the true solution, so that it is possible to do two tests with small boundaries and get a reasonable estimate of the true solution by averaging the two results.

The effect of boundary location is most noticeable for elastic bodies because the displacements and stress changes are more confined when plastic behavior is present; there is a natural cut-off distance within which most of the action occurs. The artificial boundary may be placed slightly closer without serious error. However, any artificial boundary must not be sufficiently close that it attracts plastic flow and thereby invalidates the solution.

It is always best to run several (coarse) models first, with different boundary locations, to evaluate the potential influence of the boundary on the calculated response, before performing the detailed analysis.

| Was this helpful? ... | Itasca Software © 2024, Itasca | Updated: Nov 12, 2025 |