Elastic Plate with Combined Uniform Lateral and In-Plane Loads

Problem Statement

Note

To view this project in FLAC3D, use the menu command . The main data files are shown at the end of this example. The remaining data files can be found in the project.

The displacement field for a simply supported rectangular elastic plate subjected to lateral and in-plane loads is computed and compared with the analytical solution. The lateral load produces bending stresses, and the in-plane load produces membrane stresses. Tensile membrane stresses induce a stress-stiffening effect, whereby the lateral deflection is reduced. This problem quantifies the ability of the DKT-CST hybrid shell element to model both the bending and membrane actions, and demonstrates that the stress-stiffening effect can be captured by running FLAC3D in large-strain mode.

Analytical Solution

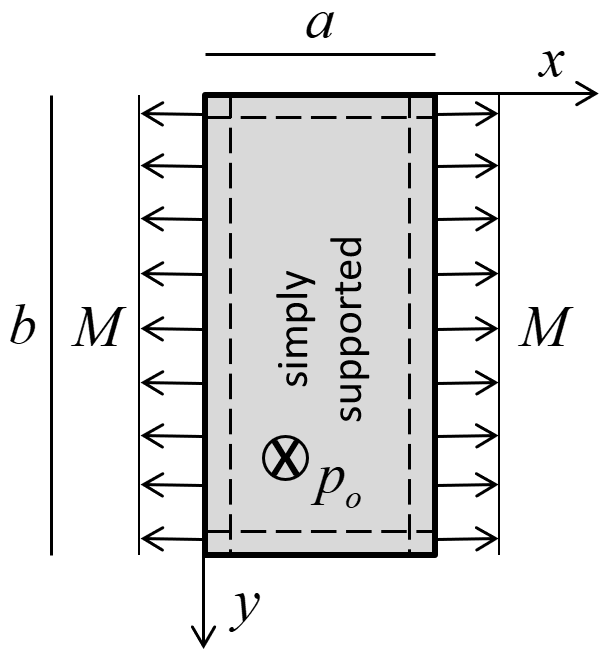

A simply supported rectangular plate (with side lengths \((a)\) and \((b)\)) is subjected to a uniform lateral load \((p_o)\) and a uniform in-plane load \((M)\). The plate has an isotropic elastic material model. The lateral load is resisted by bending action, and the in-plane load is resisted by membrane action. The solution extends the small deformation theory of plates (whereby the deflection of the midsurface is assumed to be small relative to the plate thickness) to include the straining of the midplane subsequent to combined loading. The analytical solution for lateral deflection is given by Ugural (1981, Example 7.1), and expressed via the notation in Figure 1.

Figure 1: Rectangular plate, lateral and in-plane loading and coordinate system used to express the analytical solution.

The lateral deflection is given by

where \(p_o\) is uniform lateral load; \(M\) is uniform in-plane load; \(D\) is flexural rigidity; \(a\) is length in the \(x\) direction; \(b\) is length in the \(y\) direction; \(E\) is Young’s modulus; \(\nu\) is Poisson’s ratio; and \(t\) is plate thickness. Examination of this equation reveals that the presence of a tensile/compressive in-plane load decreases/increases the plate deflection. This is the stress-stiffening effect noted above.

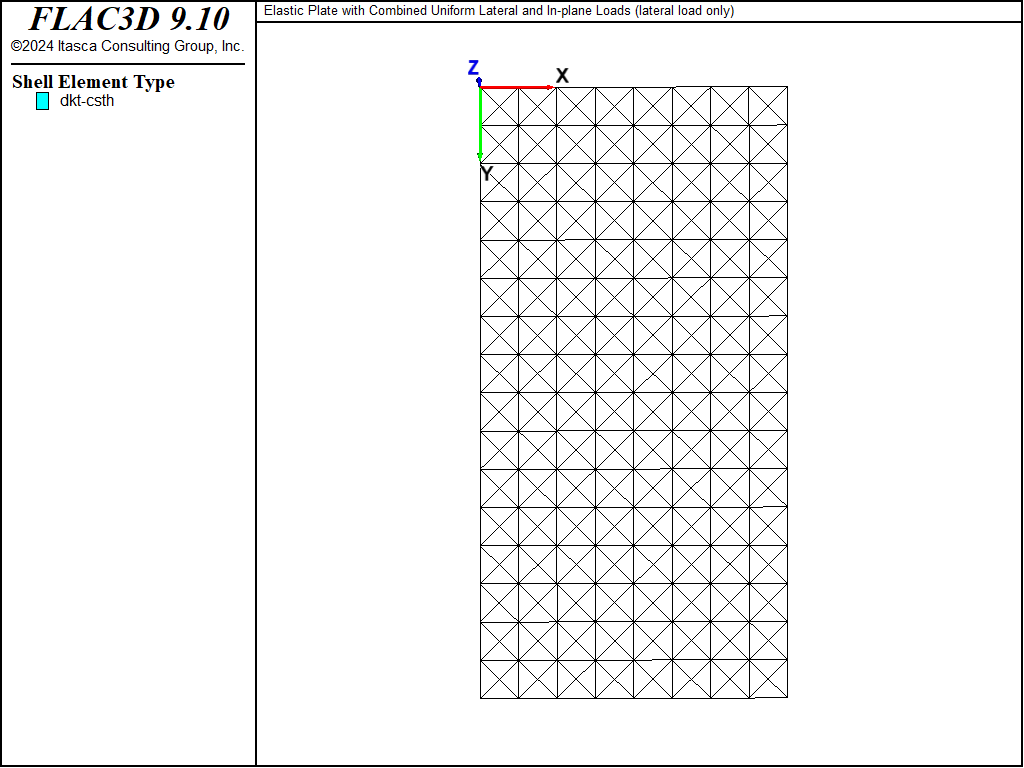

FLAC3D Model

The plate is modeled using a 16 by 8 mesh of DKT-CST Hybrid elements with a cross-diagonal pattern as shown in Figure 2. The cross-diagonal pattern is used to ensure symmetric response. The simply-supported boundary condition (translational velocity fixed in the \(z\) direction) is assigned to the nodes along the plate edges. A roller boundary condition (translational velocity fixed in the \(x\) direction) is assigned to the nodes along the \(x = 0\) edge. The lateral load is applied over the plate surface as a uniform pressure acting in the positive \(z\) direction. The in-plane load is applied along the \(x = a\) edge as a uniform force-per-unit-length via the structure node apply force-edge command. The \(z\)-displacement at the plate center is monitored as a history. Local nonviscous damping is used with a damping factor of 0.8. The model is run in large-strain mode for the combined-loads case, and in small-strain mode for the lateral load only case. The model is cycled until a convergence limit of \(1 \times 10^{-3}\) is achieved. The model response is compared with the analytical solution along the \(x = a/2\) and \(y = b/2\) lines. The analytical values are obtained by taking the first 50 terms \((m \leq 100, n \leq 100)\) of the infinite series.

Figure 2: Geometry of the FLAC3D model showing mesh and global coordinate system.

The particular properties used for this problem are defined as follows. Consider the plate to be a 4 by 8 sheet of three-quarter inch plywood that is simply supported along its edges:

The plywood is assumed to behave as an isotropic elastic material:

A box of dry sand that is one-half meter deep sits on top of the plywood sheet, inducing a uniform lateral load:

For the combined-loads case, an in-plane load of 100 kN/m acting in the positive \(x\) direction is applied along the \(x = a\) edge.

Results and Discussion

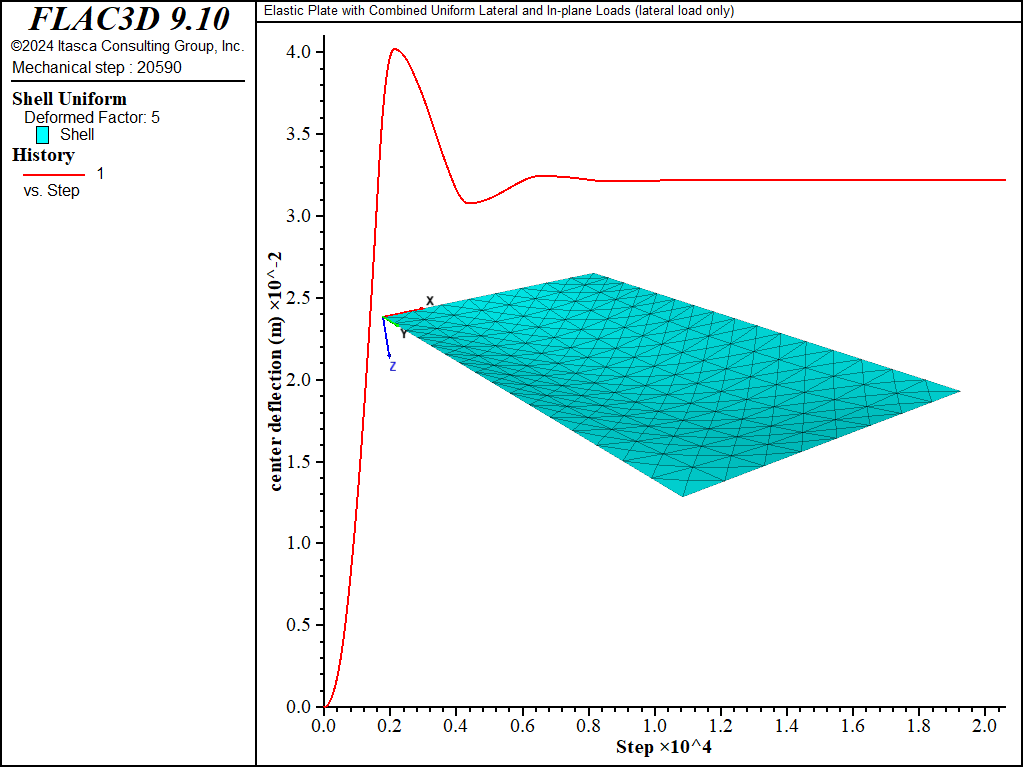

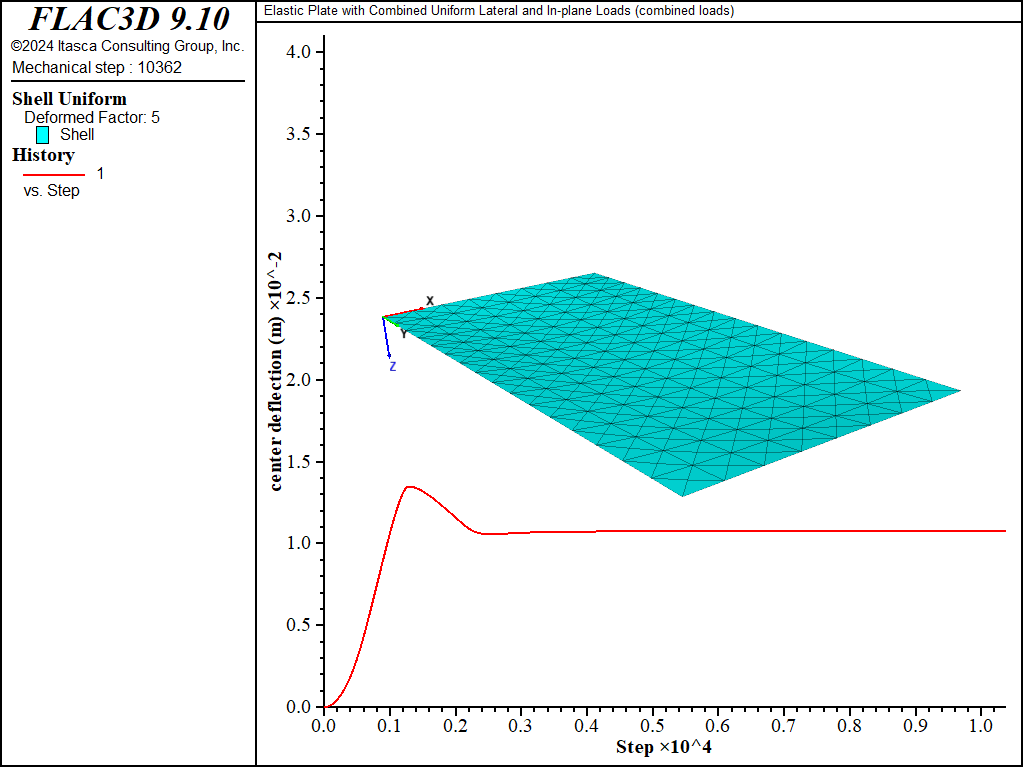

The deformed shapes and center-deflection histories for the two cases are shown in Figures 3 and 4, from which we conclude that the static solutions have been obtained. The tensile in-plane load reduces the plate deflection from approximately 32 to 11 mm.

Figure 3: Deformed shape (deformation factor: 5) and center deflection (lateral load only).

Figure 4: Deformed shape (deformation factor: 5) and center deflection (combined loads).

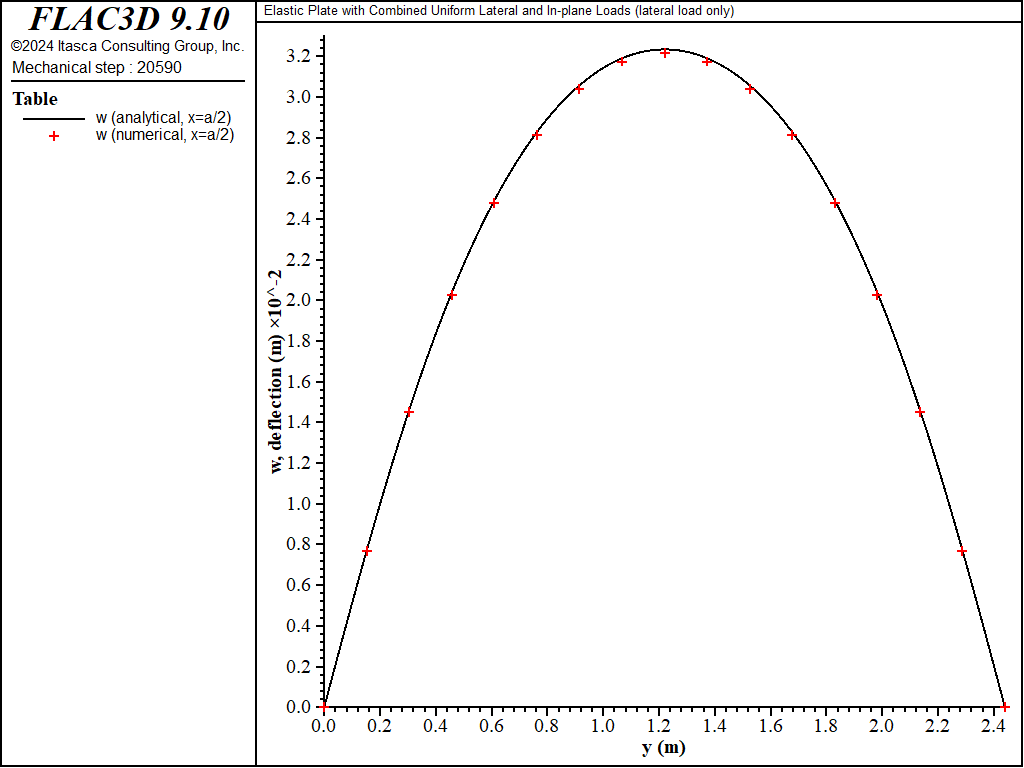

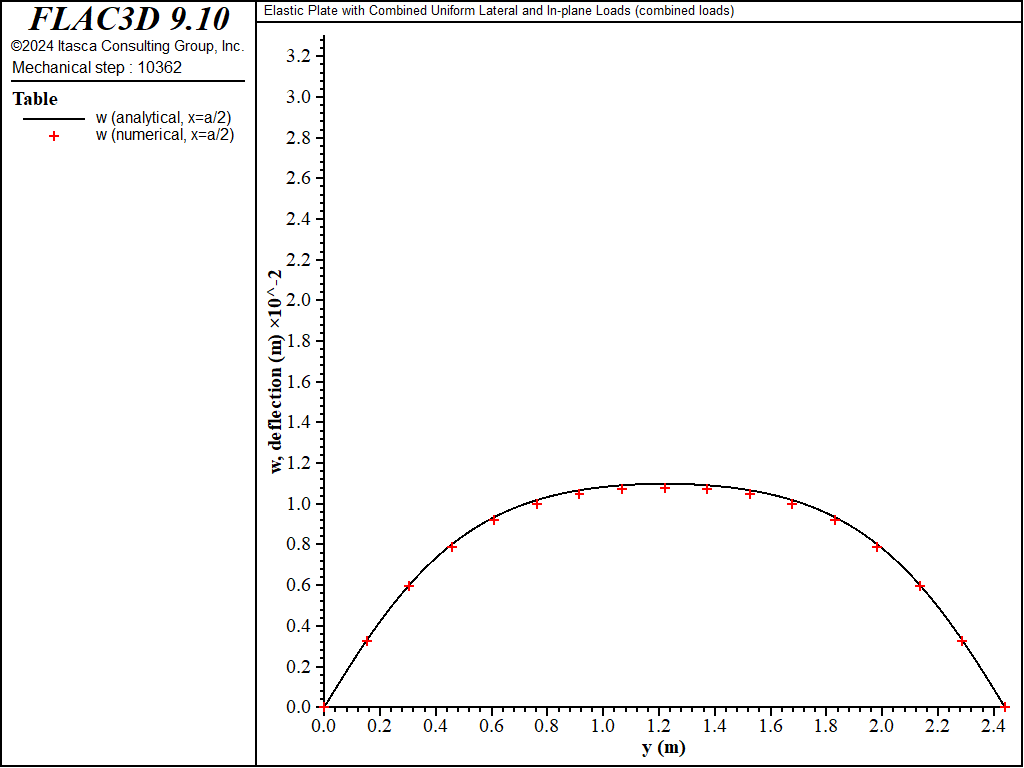

The lateral deflection is obtained from the \(z\) displacement of the nodes along the indicated line. The lateral deflection along the \(x = a/2\) line for the two cases is shown in Figures 5 and 6. The computed deflections are within 0.7% of the analytical values at all sampling locations.

Figure 5: Lateral deflection along the \(x = a/2\) line (lateral load only).

Figure 6: Lateral deflection along the \(x = a/2\) line (combined loads).

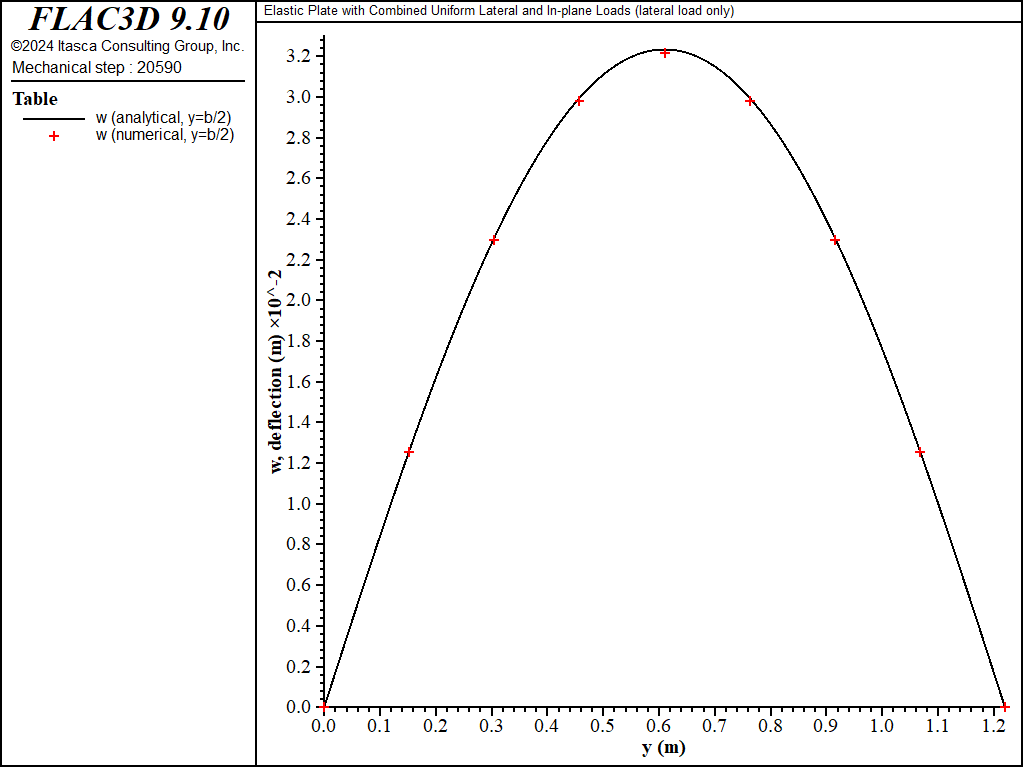

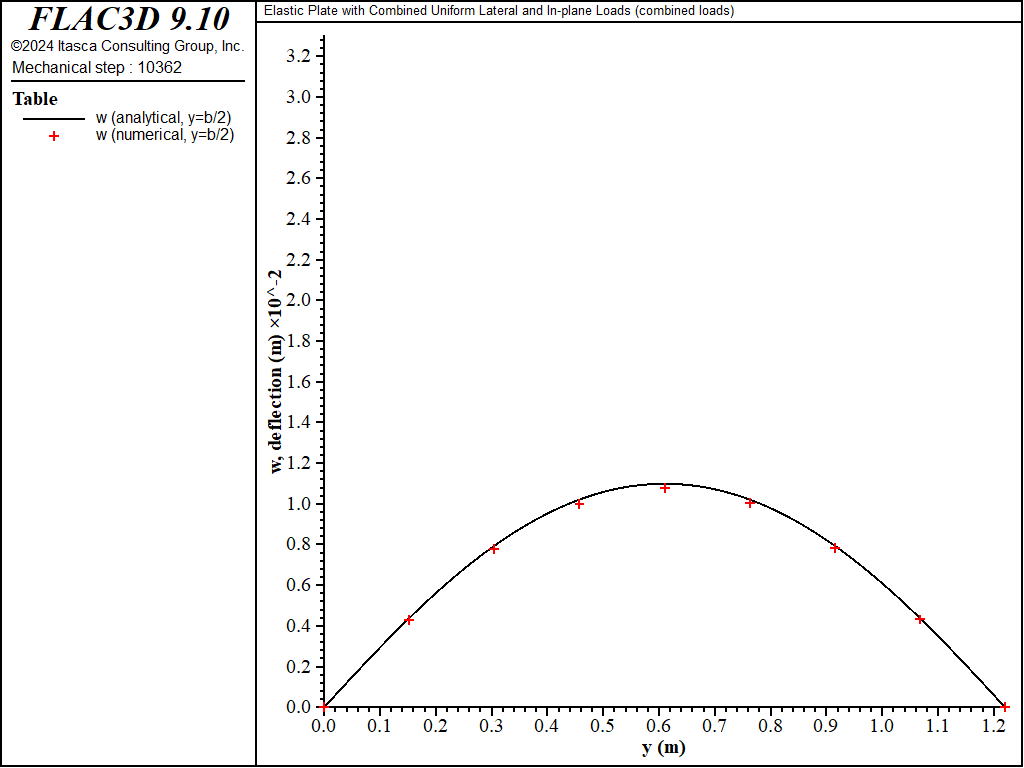

The lateral deflection along the \(y = b/2\) line for the two cases is shown in Figures 7 and 8. The computed deflections are within 2.3% of the analytical values at all sampling locations.

Figure 7: Lateral deflection along the \(y = b/2\) line (lateral load only).

Figure 8: Lateral deflection along the \(y = b/2\) line (combined loads).

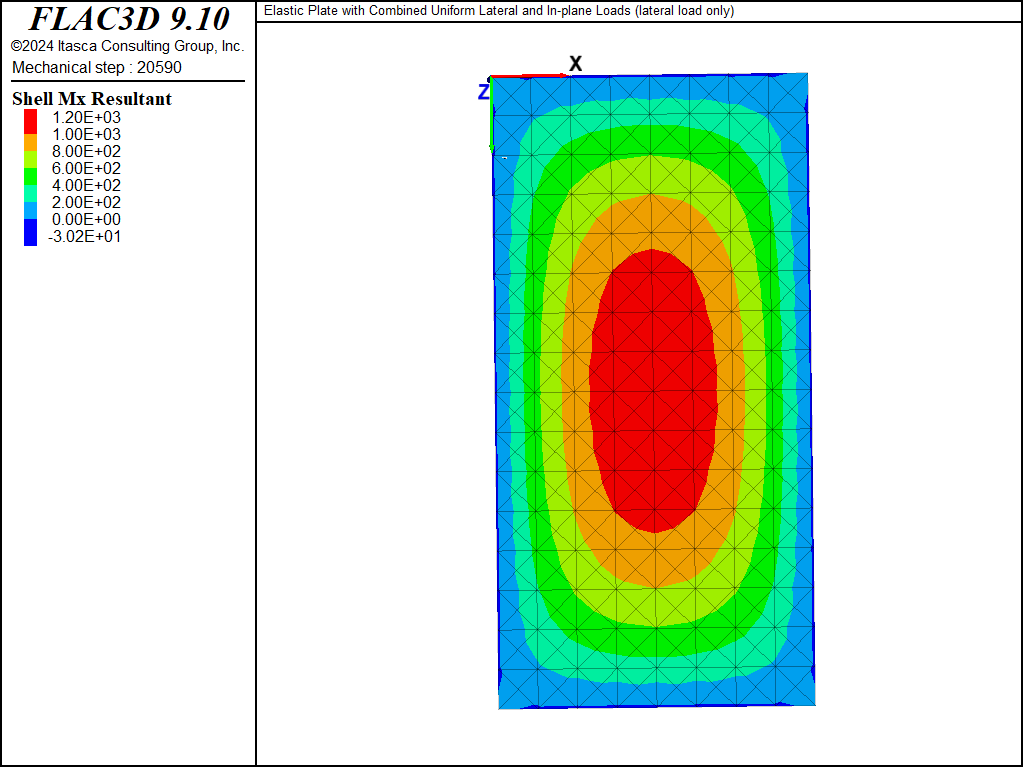

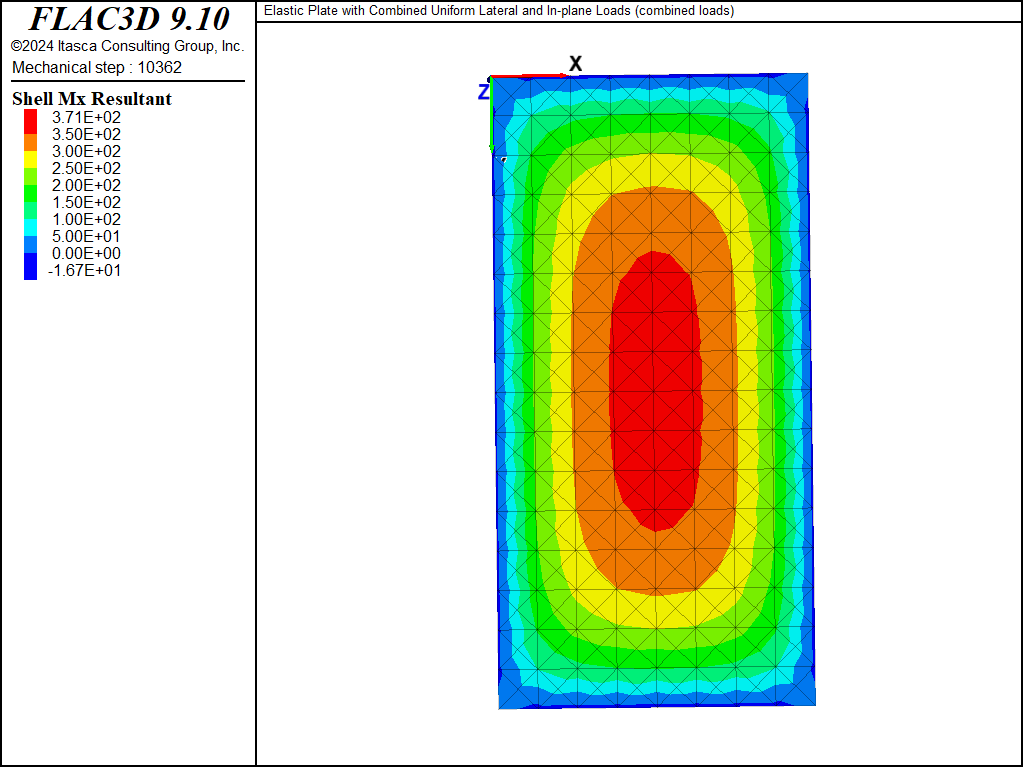

The stress resultants are expressed in a surface coordinate system that is aligned with the global coordinate system. The \(M_x\) stress resultant for the two cases is shown in Figures 9 and 10. The tensile in-plane load reduces the plate deflection, which in turn, reduces \(M_x\) from 1200 to 371 N.

Figure 9: Variation of the \(M_x\) stress resultant over the plate (lateral load only).

Figure 10: Variation of the \(M_x\) stress resultant over the plate (combined loads).

Reference

Ugural, A. C. Stresses in Plates and Shells, New York: McGraw-Hill Publishing Company, Inc. (1981).

Data Files

combinedLoad.dat

model new

fish automatic-create off

[global t = 'Elastic Plate with Combined Uniform Lateral and In-plane Loads']

model title [t + ' (combined loads)']

; =============================================================================

; Material properties, dimensions and loading (SI units)

[global E = 8.5e9] ; plywood

[global nu = 0.33]

[global t = 19e-3] ; ~ 3/4 inch

[global a = 1220e-3] ; 4 by 8 sheet

[global b = 2440e-3]

[global rho = 1602] ; dry sand

[global Ht = 500e-3] ; height of sand

[global M = 1.0e5] ; specify as positive number (N/m)

; Derived items

[global p0 = rho * 9.81 * Ht] ; units: N/m*m

[global D = E*t*t*t/(12 * (1 - nu*nu))

; Mesh properties

[global crossDiag = true]

[global nx = 8] ; should be even

[global ny = 16] ; should be even

; =============================================================================

; Create mesh, assign shell properties, BCs and loads.

structure shell create by-quadrilateral (0,0,0) ([a],0,0) ([a],[b],0) (0,[b],0) ...

size [nx] [ny] cross-diagonal [crossDiag] element-type dkt-csth

structure shell property thickness [t]

structure shell cmodel assign elastic

structure shell property young [E] poisson [nu]

structure node fix velocity-z range position-y 0.0 position-y [b] ...

position-x 0.0 position-x [a] union

structure node fix velocity-x range position-x 0.0

structure shell apply [p0]

structure node apply force-edge [M] 0 0 range position-x [a]

structure node history displacement-z position [0.5*a] [0.5*b] 0 ; plate center

model large-strain true ; for M > 0 (membrane-bending coupling)

structure mechanical damping local 0.8

model solve convergence 1e-3

structure shell recover surface 1 0 0 ; align with the global x and y direcs.

structure shell recover resultants

model save 'combinedLoad'

lateralLoadOnly.dat

model new

fish automatic-create off

[global t = 'Elastic Plate with Combined Uniform Lateral and In-plane Loads']

model title [t + ' (lateral load only)']

; =============================================================================

; Material properties, dimensions and loading (SI units)

[global E = 8.5e9] ; plywood

[global nu = 0.33]

[global t = 19e-3] ; ~ 3/4 inch

[global a = 1220e-3] ; 4 by 8 sheet

[global b = 2440e-3]

[global rho = 1602] ; dry sand

[global Ht = 500e-3] ; height of sand

[global M = 0.0] ; specify as positive number (N/m)

; Derived items

[global p0 = rho * 9.81 * Ht] ; units: N/m*m

[global D = E*t*t*t/(12 * (1 - nu*nu))

; Mesh properties

[global crossDiag = true]

[global nx = 8] ; should be even

[global ny = 16] ; should be even

; =============================================================================

; Create mesh, assign shell properties, BCs and loads.

structure shell create by-quadrilateral (0,0,0) ([a],0,0) ([a],[b],0) (0,[b],0) ...

size [nx] [ny] cross-diagonal [crossDiag] element-type dkt-csth

structure shell property thickness [t]

structure shell cmodel assign elastic

structure shell property young [E] poisson [nu]

structure node fix velocity-z range position-y 0.0 position-y [b] ...

position-x 0.0 position-x [a] union

structure node fix velocity-x range position-x 0.0

structure shell apply [p0]

structure node apply force-edge [M] 0 0 range position-x [a]

structure node history displacement-z position [0.5*a] [0.5*b] 0 ; plate center

model large-strain false ; for M = 0 (no membrane-bending coupling)

structure mechanical damping local 0.8

model solve convergence 1e-3

structure shell recover surface 1 0 0 ; align with the global x and y direcs.

structure shell recover resultants

model save 'lateralLoadOnly'

⇐ Elastic Plate (Orthotropic) with Uniform Lateral Load | Elastic Shell (Cylindrical Concrete Vault) ⇒

| Was this helpful? ... | Itasca Software © 2024, Itasca | Updated: Aug 13, 2024 |