Example: Shear and tension test for rockbolt crossing a joint

Problem Statement

Note

To view this project in 3DEC, use the menu command . Choose “BlockSel/ Rockbolts” and select “rockbolts.prj” to load. The data files used are shown at the end of this example.

This example simulates shearing and tension on a single joint supported by a rockbolt. This test mimics the examples for hybrid bolts described in Structural Elements.

Simple Shear Test

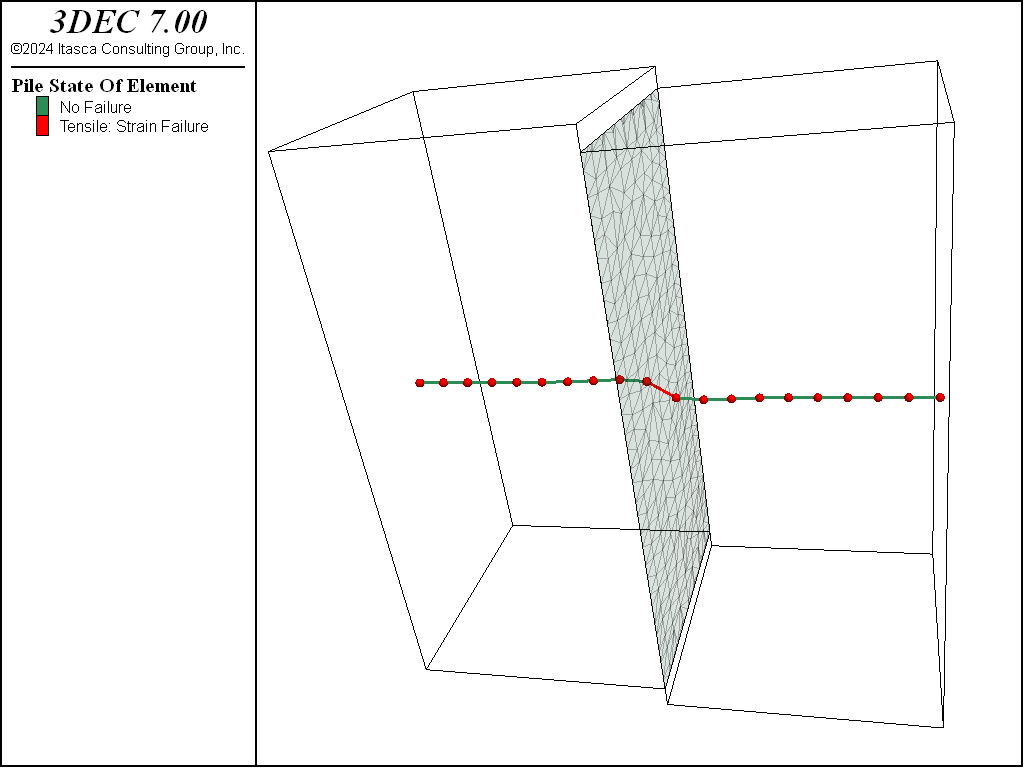

A simple shear test is simulated using two blocks (Figure 1). The bottom of the left block is prevented from moving in the vertical direction and the top of the right block is moved downwards at a constant velocity. A rockbolt spans the joint from left to right. A normal stress of 1 MPa is applied. The friction angle of the joint is set to 40º and the cohesion is 0.

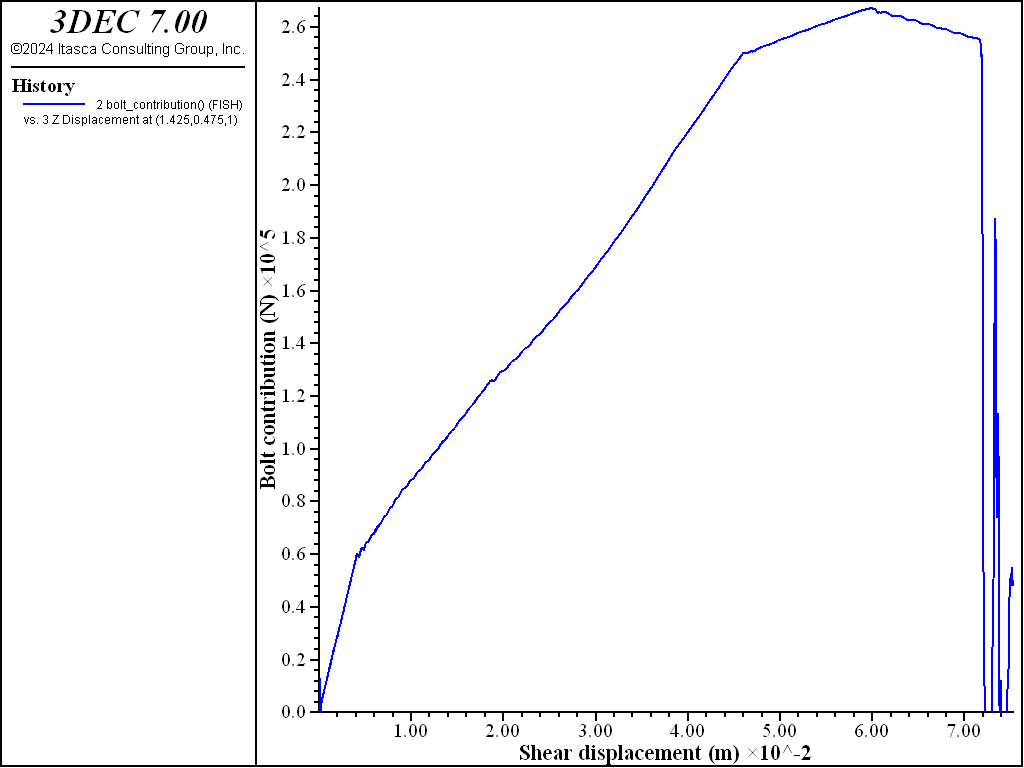

Figure 2 shows the bolt contribution versus shear displacement. The bolt contribution is essentially the shear stress minus the frictional strength (\(\sigma_n \tan \phi\)). At about 4 mm of shear displacement, the moment limit is exceeded and plastic hinges form. At about 4.5 cm, the bolt itself yields in tension. Finally after about 5 cm of shear, the bolt hits the strain limit and ruptures.

blocks.dat

;

;Build model for hybrid bolt calibration

;

model new

fish automatic-create off

model random 10000

model large-strain on

;

fish define params

; block dimensions

global block_lenH = 0.95

global block_lenV = 2.0

global edge_length_=0.125 ; zone size

; block properties

global ymod_=40e9

global pratio_=0.25

global dens_=2500

; joint properties

global jkn_=3e11

global jks_=3e11

global jfric_=40.0

; --- rockbolt parameters ----

; cable

global area_=201e-6

global e_=1.4e11

global grout_stiff_=3e8

global grout_strength_=2e5

global cable_yield_=100e3

global cable_strain_limit_=0.05 ; PLASTIC tensile strain limit

global segment_length_=0.1

; pile

global poiss_ = 0.2

global moi_=5e-5

global plastic_moment_=1e4

global nstiff_ = 1e8

; calculated parameters

global bolt_len=block_lenH*2.

end

[params]

=====================================================

;

;make 2 blocks

block create brick 0 [block_lenH] 0 [block_lenH] 0 [block_lenV]

block create brick [block_lenH] [2*block_lenH] 0 [block_lenH] 0 [block_lenV]

block zone generate edgelength [edge_length_]

; zone and contact properties

block zone cmodel elastic

block zone property young [ymod_] poisson [pratio_] density [dens_]

block contact jmodel assign mohr

block contact property stiffness-normal [jkn_] stiffness-shear [jks_] friction [jfric_]

block contact mat-table default prop stiffness-normal [jkn_] stiffness-shear [jks_] friction [jfric_]

;

; apply common boundary conditions

block hide range position-x 0 [block_lenH] not

block gridpoint apply velocity-z 0 range position-z 0

block hide off

;

block gridpoint apply velocity-y 0 range position-z -1000 1000

; use combined damping to stop vibrations.

block mech damp combined

model save 'blocks'

shear_test.dat

;;-------------------------------------------------------------------------------------------

;; Shear test

;;-------------------------------------------------------------------------------------------

model rest 'blocks'

; define parameters for shear loading

fish def params_shear

; boundary conditions

global normal_stress = 1.0e6

global zvel_=-0.01

; calculated values

local normal_force = normal_stress * block_lenH*block_lenV

global friction_force = normal_force*math.tan(jfric_*math.degrad)

end

[params_shear]

; boundary conditions

block face apply stress-xx [-1.0*normal_stress] range position-x 0

block face apply stress-xx [-1.*normal_stress] range position-x [block_lenH*2.]

;

block hide range position-x 0 [block_lenH]

block gridpoint group 'top' range pos-z [block_lenV]

block hide off

model solve

;

block gridpoint initialize displacement 0 0 0

block contact reset displacement

;

; Function to calculate bolt contribution to resisting shear load

[global max_force = 0.0]

[global bolt_contribution = 0.0]

;

fish define reaction_force

local temp_ = 0.0

loop foreach local gi block.gp.list

if block.gp.group(gi) = 'top'

temp_ = temp_ - block.gp.force.reaction.z(gi)

end_if

end_loop

reaction_force = temp_

bolt_contribution = temp_ - friction_force

end

;

fish history reaction_force

fish history bolt_contribution

block history displacement-z ...

position [1.5*block_lenH] [0.5*block_lenH] [0.5*block_lenV]

model history mechanical unbalanced-maximum

;to run the test - stop at 5 cm of shear displacement

fish def run_it

local test_ = true

local gp_ = block.gp.near(1.5*block_lenH,0.5*block_lenH,0.5*block_lenV)

loop while test_ = true

command

model cycle 10000

end_command

if block.gp.dis.z(gp_) < -0.07

test_ = false

end_if

end_loop

end

model save 'ini_shear.sav'

=================================================================

; Test perpendicular bolt 90 degrees

; Change dincl_ to test other bolt angles

;

model restore 'ini_shear'

[global dincl_=90.]

;To create bolt

[global x1 = block_lenH-0.5*bolt_len*math.sin(dincl_*math.degrad)+0.001]

[global y1 = 0.5*block_lenH]

[global z1 = 0.5*block_lenV+0.5*bolt_len*math.cos(dincl_*math.degrad)]

[global x2 = block_lenH+0.5*bolt_len*math.sin(dincl_*math.degrad)-0.001]

[global y2 = y1]

[global z2 = 0.5*block_lenV-0.5*bolt_len*math.cos(dincl_*math.degrad)]

[global bolt_beg=vector(x1,y1,z1)]

[global bolt_end=vector(x2,y2,z2)]

struct pile create by-line [bolt_beg] [bolt_end] ...

max-length [segment_length_]

; cable properties

struct pile prop cross-sectional-area [area_] young [e_] ...

poiss [poiss_] coupling-stiffness-shear [grout_stiff_] ...

coupling-cohesion-shear [grout_strength_] ...

yield-tension [cable_yield_] tensile-failure-strain [cable_strain_limit_]

; pile/rockbolt properties

struct pile prop rockbolt-flag on moi-y [moi_] moi-z [moi_] ...

moi-polar [moi_*10] plastic-moment [plastic_moment_] ...

coupling-stiffness-normal [nstiff_] coupling-cohesion-normal 1e20

;to plate both ends:

struct link attach x rigid y rigid z rigid range pos-x [bolt_beg->x]

struct link attach x rigid y rigid z rigid range pos-x [bolt_end->x]

struct mech damp combined-local

; ramp up shear load over 10000 steps

[global cyc0 = mech.cycle]

fish def ramp

ramp = (mech.cycle - cyc0)/10000.0

end

block gridpoint apply vel-z [zvel_] fish ramp range group 'top'

model cycle 10000

; re-apply load without ramp

block gridpoint apply vel-z [zvel_] range group 'top'

;run the test - stop when rupture

[run_it]

model save 'shear-90'

program return

=================================================================

; Test bolt at 70 degrees

;

model restore 'ini_shear'

[global dincl_=70.]

;To create Inclined bolt

[global x1 = block_lenH-0.5*bolt_len*math.sin(dincl_*math.degrad)+0.001]

[global y1 = 0.5*block_lenH]

[global z1 = 0.5*block_lenV+0.5*bolt_len*math.cos(dincl_*math.degrad)]

[global x2 = block_lenH+0.5*bolt_len*math.sin(dincl_*math.degrad)-0.001]

[global y2 = y1]

[global z2 = 0.5*block_lenV-0.5*bolt_len*math.cos(dincl_*math.degrad)]

[global bolt_beg=vector(x1,y1,z1)]

[global bolt_end=vector(x2,y2,z2)]

struct pile create by-line [bolt_beg] [bolt_end] ...

max-length [segment_length_]

; cable properties

struct pile prop cross-sectional-area [area_] young [e_] ...

poiss [poiss_] coupling-stiffness-shear [grout_stiff_] ...

coupling-cohesion-shear [grout_strength_] ...

yield-tension [cable_yield_] tensile-failure-strain [cable_strain_limit_]

; pile/rockbolt properties

struct pile prop rockbolt-flag on moi-y [moi_] moi-z [moi_] ...

moi-polar [moi_*10] plastic-moment [plastic_moment_] ...

coupling-stiffness-normal [nstiff_] coupling-cohesion-normal 1e20

;to plate both ends:

struct link attach x rigid y rigid z rigid range pos-x [bolt_beg->x]

struct link attach x rigid y rigid z rigid range pos-x [bolt_end->x]

struct mech damp combined-local

; ramp up shear load over 10000 steps

[global cyc0 = mech.cycle]

fish def ramp

ramp = (mech.cycle - cyc0)/10000.0

end

block gridpoint apply vel-z [zvel_] fish ramp range group 'top'

model cycle 10000

; re-apply load without ramp

block gridpoint apply vel-z [zvel_] range group 'top'

;run the test - stop when rupture

[run_it]

model save 'shear-70'

Simple Tension Test

The same block and bolt configuration from the simple shear test is used in the tension test. In this case no normal stress is applied and the right boundary of the right block is moved to the right at a constant velocity.

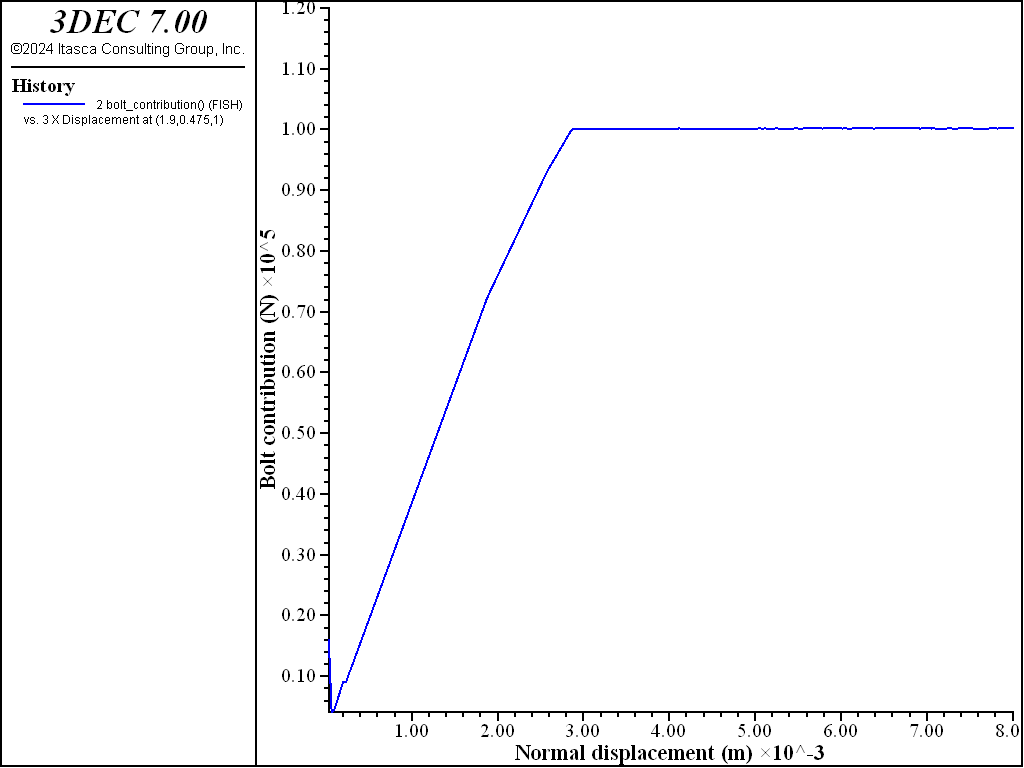

Figure 3 shows the block and cable configuration at the end of the test. Figure 4 shows the bolt contribution in this test. Since there is no tensile strength on the joint, the bolt contribution is simply equal to the tensile force applied at the right boundary. This plot shows the initial elastic axial deformation, and then the start of grout failure at around 1.7 mm of displacement. The bolt yields in tension after 2.5 mm of pull, at which time the bolt behaves plastically and the contribution no longer increases. Fnally, the bolt ruptures at about 7.5 mm of opening.

pullout.dat

;;-------------------------------------------------------------------------------------------

;; Pull-out test

;;-------------------------------------------------------------------------------------------

model restore 'blocks'

;

; Define parameters for pullout test

[global xvel_ = 1e-2]

;

block gridpoint apply velocity-x 0 range position-x 0

;

block hide range position-x 0 [block_lenH]

block gridpoint apply velocity-z 0 range position-z 0

block gridpoint group 'right' range pos-x [block_lenH]

block hide off

;

[global max_force = 0.0]

[global bolt_contribution = 0.0]

;

fish define reaction_force

local temp_ = 0.0

loop foreach local gi block.gp.list

if block.gp.group(gi) = 'right'

temp_ = temp_ + block.gp.force.reaction.x(gi)

end_if

end_loop

reaction_force = math.abs(temp_)

bolt_contribution = math.abs(temp_); - friction_force

end

;

fish history reaction_force

fish history bolt_contribution

block history displacement-x ...

position [2*block_lenH] [0.5*block_lenH] [0.5*block_lenV]

model history mechanical unbalanced-maximum

;fish function to run the test - stop when displacement = 1 cm

[global gp_monitor = block.gp.near(2*block_lenH,0.5*block_lenH,0.5*block_lenV)]

fish def run_it

local test_ = true

loop while test_ = true

command

model cycle 10000

end_command

if math.mag(block.gp.dis(gp_monitor)) > 8e-3

test_ = false

endif

end_loop

end

;

model save 'ini_pull'

;

=================================================================

;

; Test perpendicular bolt 90 degrees

; Change dincl_ to test other bolt angles

;

model restore 'ini_pull'

[global dincl_=90.]

;To create bolt

[global x1 = block_lenH-0.5*bolt_len*math.sin(dincl_*math.degrad)+0.001]

[global y1 = 0.5*block_lenH]

[global z1 = 0.5*block_lenV+0.5*bolt_len*math.cos(dincl_*math.degrad)]

[global x2 = block_lenH+0.5*bolt_len*math.sin(dincl_*math.degrad)-0.001]

[global y2 = y1]

[global z2 = 0.5*block_lenV-0.5*bolt_len*math.cos(dincl_*math.degrad)]

[global bolt_beg=vector(x1,y1,z1)]

[global bolt_end=vector(x2,y2,z2)]

struct pile create by-line [bolt_beg] [bolt_end] ...

max-length [segment_length_]

; cable properties

struct pile prop cross-sectional-area [area_] young [e_] ...

poiss [poiss_] coupling-stiffness-shear [grout_stiff_] ...

coupling-cohesion-shear [grout_strength_] ...

yield-tension [cable_yield_] tensile-failure-strain [cable_strain_limit_]

; pile/rockbolt properties

struct pile prop rockbolt-flag on moi-y [moi_] moi-z [moi_] ...

moi-polar [moi_*10] plastic-moment [plastic_moment_] ...

coupling-stiffness-normal [nstiff_] coupling-cohesion-normal 1e20

struct mech damp combined-local

; ramp up tensile load over 10000 steps

[global cyc0 = mech.cycle]

fish def ramp

ramp = (mech.cycle - cyc0)/10000.0

end

block gridpoint apply vel-x [xvel_] fish ramp range group 'right'

model cycle 10000

[run_it]

model save 'pull-90'

program return

===============================================================================

;inclined bolt 70 degrees

model restore 'ini_pull'

[global dincl_=70.]

;To create inclined bolt

[global x1 = block_lenH-0.5*bolt_len*math.sin(dincl_*math.degrad)+0.001]

[global y1 = 0.5*block_lenH]

[global z1 = 0.5*block_lenV+0.5*bolt_len*math.cos(dincl_*math.degrad)]

[global x2 = block_lenH+0.5*bolt_len*math.sin(dincl_*math.degrad)-0.001]

[global y2 = y1]

[global z2 = 0.5*block_lenV-0.5*bolt_len*math.cos(dincl_*math.degrad)]

[global bolt_beg=vector(x1,y1,z1)]

[global bolt_end=vector(x2,y2,z2)]

struct pile create by-line [bolt_beg] [bolt_end] ...

max-length [segment_length_]

; cable properties

struct pile prop cross-sectional-area [area_] young [e_] ...

poiss [poiss_] coupling-stiffness-shear [grout_stiff_] ...

coupling-cohesion-shear [grout_strength_] ...

yield-tension [cable_yield_] tensile-failure-strain [cable_strain_limit_]

; pile/rockbolt properties

struct pile prop rockbolt-flag on moi-y [moi_] moi-z [moi_] ...

moi-polar [moi_*10] plastic-moment [plastic_moment_] ...

coupling-stiffness-normal [nstiff_] coupling-cohesion-normal 1e20

;to plate both ends:

struct link attach x rigid y rigid z rigid range pos-x [bolt_beg->x]

struct link attach x rigid y rigid z rigid range pos-x [bolt_end->x]

; ramp up tensile load over 10000 steps

[global cyc0 = mech.cycle]

fish def ramp

ramp = (mech.cycle - cyc0)/10000.0

end

block gridpoint apply vel-x [xvel_] fish ramp range group 'right'

model cycle 10000

[run_it]

model save 'pull-70'

;-------------------------------------------------------------------------------------------

;end of file

| Was this helpful? ... | 3DEC © 2019, Itasca | Updated: Feb 25, 2024 |