Oedometer Test with Mohr-Coulomb Model

Note

The project file for this example is available to be viewed/run in FLAC3D.[1] The project’s main data file is shown at the end of this example.

This example concerns the determination of stresses in a Mohr-Coulomb material subjected to an oedometer test. In this experiment, two of the principal stress components are equal and, during plastic flow, the stress point evolves along a vertex of the Mohr-Coulomb criterion representation in the \(\Pi\)-plane (the iso-pressure (\(\sigma_{kk}\) = constant) plane in the principal stress space). The purpose is to validate the numerical technique adopted in FLAC3D to handle such a situation. Note that FLAC3D uses no special techniques to deal with yield at vertex points of the Mohr-Coulomb failure locus in the \(\Pi\) plane. Results of a numerical experiment are presented and compared to an exact solution.

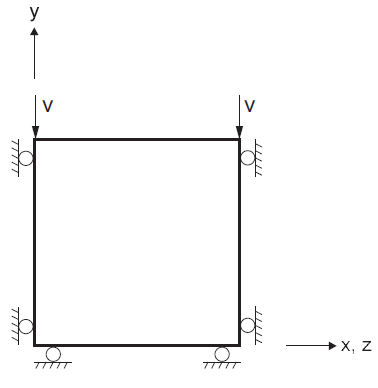

The boundary conditions for the oedometric test are sketched in Figure 1. They correspond to the uniform strain rates

where \(v\) is the constant \(y\)-component of the velocity applied to the sample \((v < 0)\), and \(L\) is the height of the sample.

Assuming zero initial stresses, the principal directions of stresses and strains are those of the coordinate axes. For simplicity, we consider a sample of unit height \(L\) = 1.

Figure 1: Boundary conditions for oedometer test.

In the elastic range, application of Hooke’s law gives, using \({\epsilon}_{22} = v t\) at time \(t\):

where \(\alpha_1 = K + 4/3 G\) and \(\alpha_2 = K - 2/3 G\).

To apply the Mohr-Coulomb failure criterion, we consider the yield functions

At the onset of yield, \(f^1 = f^2\) = 0 and, using Equations (2) and (3), we find

Hence, yielding will only take place provided \(\alpha_1 - \alpha_2 N_{\phi} >\) 0.

During plastic flow, the strain increments are composed of elastic and plastic parts, and we have

Using the boundary conditions of Equation (1):

The flow rule for plastic flow along the edge of the Mohr-Coulomb criterion corresponding to \({\sigma}_{11} = {\sigma}_{33}\) has the form (e.g., see Drescher 1991)

where \(g^1\) and \(g^2\) are the potential functions corresponding to \(f^1\) and \(f^2\):

After partial differentiation, Equation (7) becomes

In further considering that by symmetry \(\lambda_1 = \lambda_2\), we obtain

The stress increments, derived from Hooke’s law, are given by the relations

where we have used the symmetry condition \(\Delta {\epsilon}_{11}^e = \Delta {\epsilon}_{33}^e\).

Substitution of Equation (6) in Equation (11) yields, using Equation (10):

The parameter \(\lambda_1\) can now be determined by expressing the condition that during plastic flow, \(\Delta f^1\) = 0. Using Equation (3), this condition takes the form

Substitution of Equation (12) in Equation (13) yields, after some manipulations, the expression

where

The FLAC3D simulation is carried out using a single zone of unit dimensions. Several properties are used in conjunction with the Mohr-Coulomb model:

| bulk modulus | 200 MPa |

| shear modulus | 200 MPa |

| cohesion | 1 MPa |

| friction | 10° |

| dilation | 10° and 0° |

| tension | 5.67 MPa |

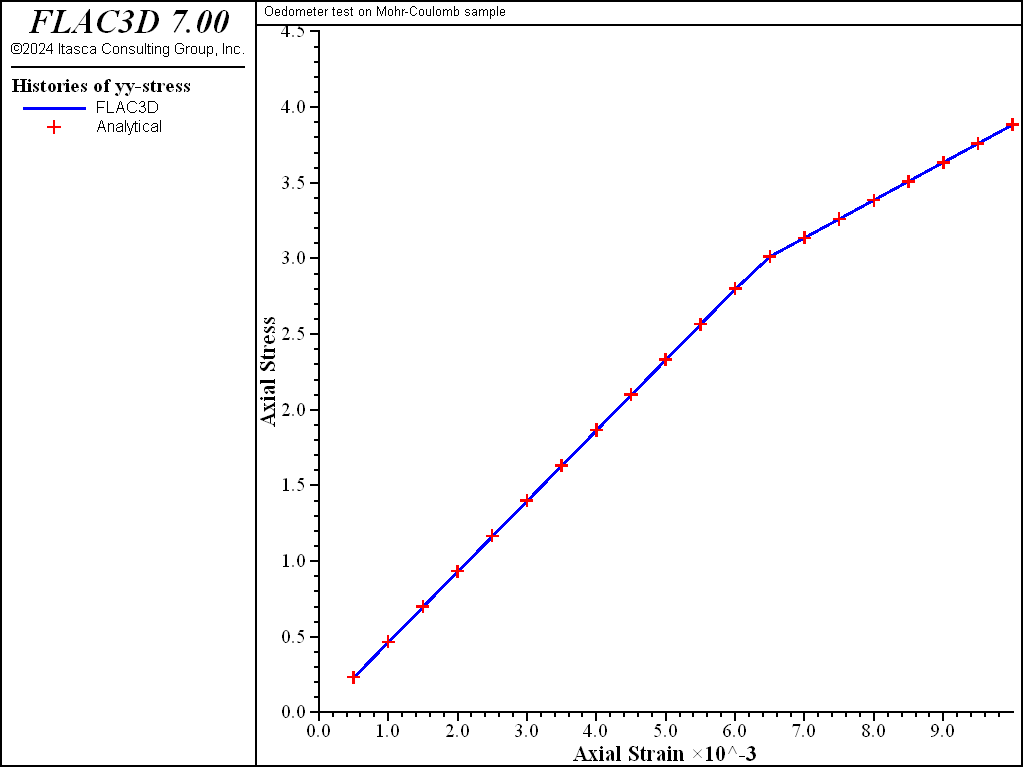

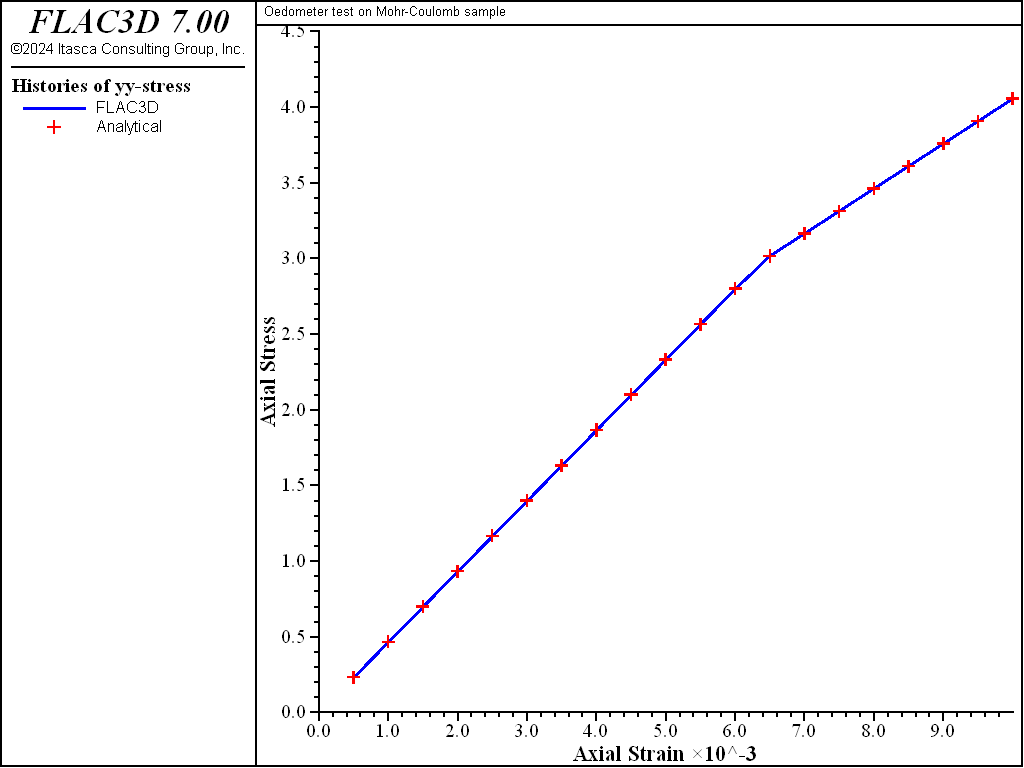

The velocity components are fixed in the \(x\)-, \(y\)-, and \(z\)-directions. A velocity of magnitude 10-5 m/steps is applied to the top of the model in the negative \(y\)-direction for a total of 1000 steps. The stress and displacement components in the \(y\)-direction are monitored and compared to the analytic prediction obtained from Equations (2), (4), and (12), using Equations (14) and (15). Two runs are carried out with values of 10° and 0° for the dilation parameter. The match is very good, as can be seen in Figure 2 and Figure 3, where numerical and analytic solutions coincide at the precision of the plot resolution.

Data File

OedometerMohrCoulomb.dat

;---------------------------------------------------------------------

; oedometer test

; check plastic flow along an edge of the Mohr-Coulomb criterion

;---------------------------------------------------------------------

model new

model large-strain off

fish automatic-create off

zone create brick size 1 1 1

model title "Oedometer test on Mohr-Coulomb sample"

zone cmodel assign mohr-coulomb

zone property bulk 200 shear 200 co 1 friction 10 tension 5.67

[global vyv = -1.e-5]

program call 'oedometerTheoretical'

zone gridpoint fix velocity

zone gridpoint initialize velocity-y [vyv] range position-y 1.0

history interval 50

zone history displacement-y position 0 1 0

fish history n_sy

fish history a_sy

model save 'ini'

; --- dilation 10

zone property dil 10

[d_sigy]

model step 1000

model save 'dil10'

; --- dilation 0

model restore 'ini'

zone property dil 0

[d_sigy]

model step 1000

model save 'dil0'

Endnotes

| [1] | To view this project in FLAC3D, use the program menu.

⮡ FLAC |

| Was this helpful? ... | FLAC3D © 2019, Itasca | Updated: Feb 25, 2024 |