Cable-Reinforced Beam

Problem Statement

Note

To view this project in FLAC2D, use the menu command . The main data files used are shown at the end of this example. The remaining data files can be found in the project.

This example illustrates the behavior of a simply supported, lightly reinforced beam subjected to gravity loading. Cable elements are used to represent the reinforcement.

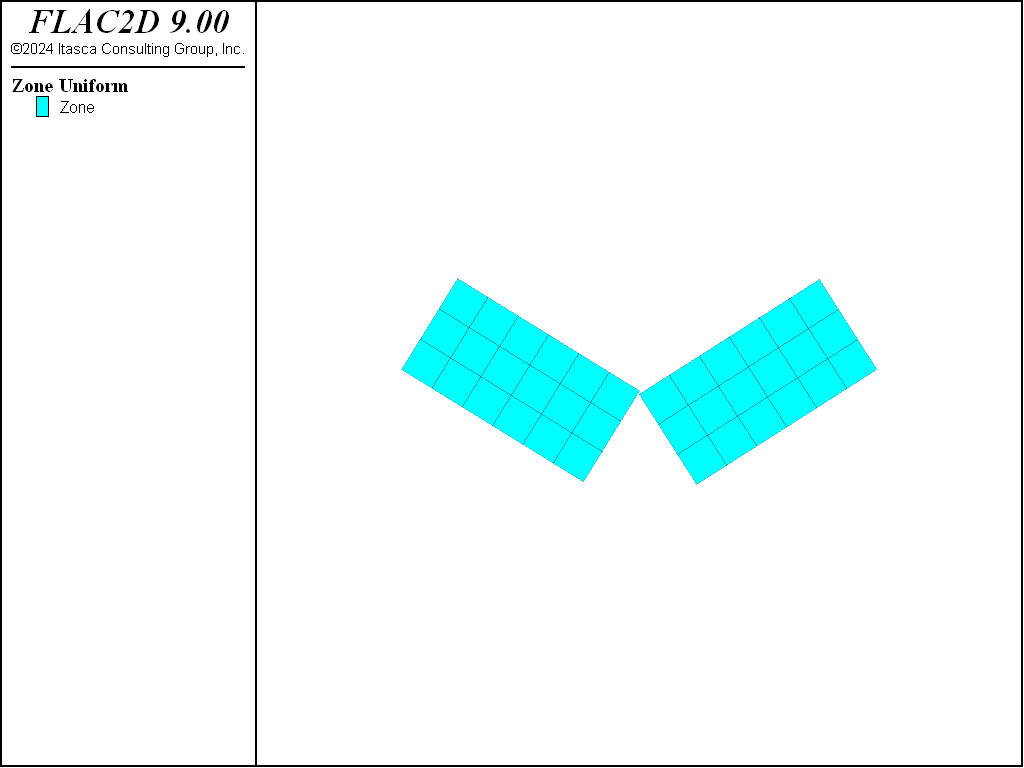

A vertical crack is created through the beam center by adding a zero-strength interface. If the model is run without reinforcement (by removing the structure cable create commands), the system behaves as two separate pieces that separate at the interface. The two blocks are supported on rollers; thus, they can move away from one another as the system collapses (see Figure 1).

Figure 1: Structural configuration after 3000 cycles (no cable present).

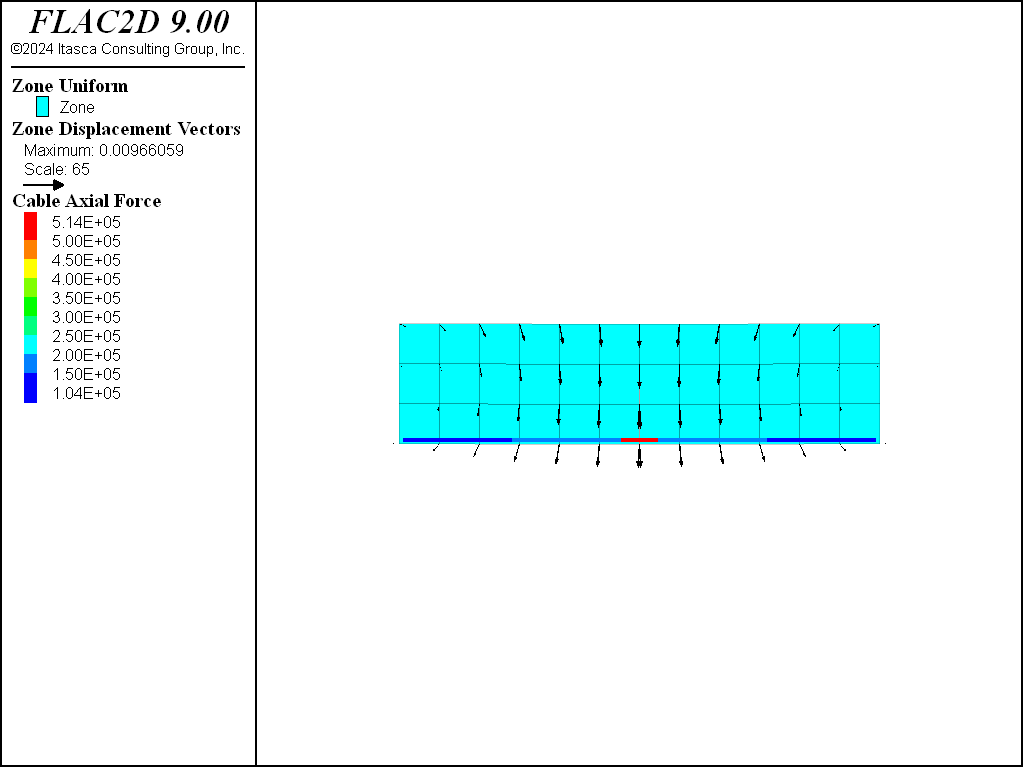

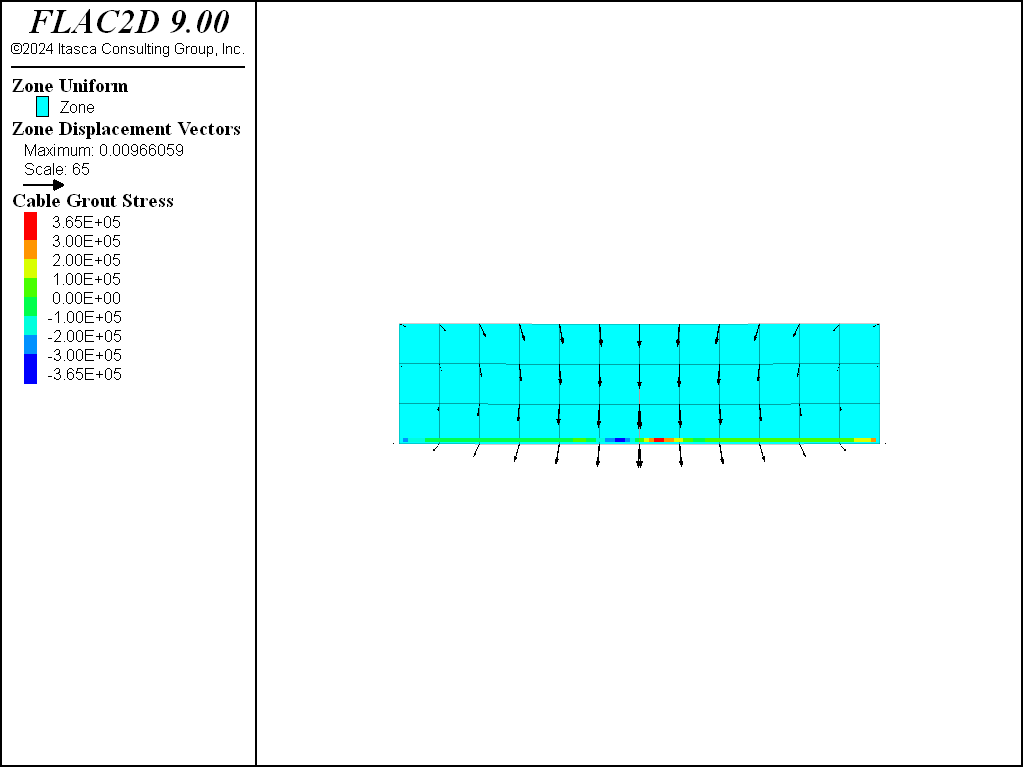

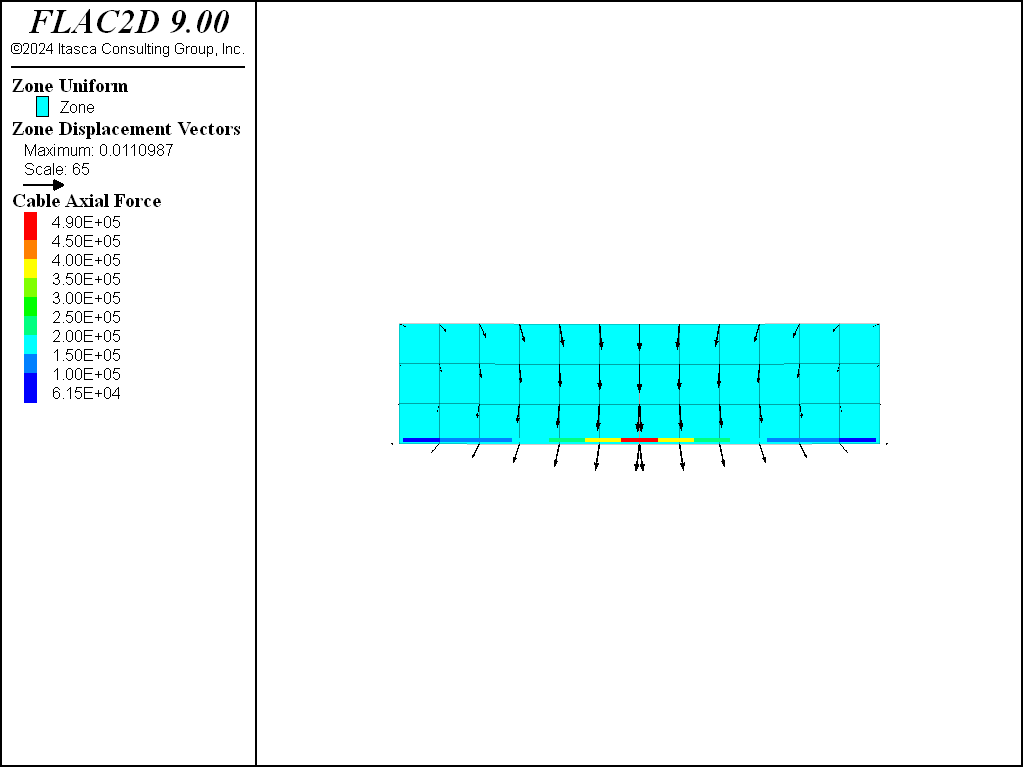

If the model is rerun with a cable inserted within the beam near its bottom fiber, then the cable carries the tension that develops in the lower portion of the beam. The final axial force distribution in the cable after the model has stabilized is shown in Figure 2. These tensile forces in the cable are produced by the grout stresses that have developed along the cable length (see Figure 3). The maximum vertical center line displacement is approximately 9.66 mm.

Figure 2: Final axial force distribution in cable.

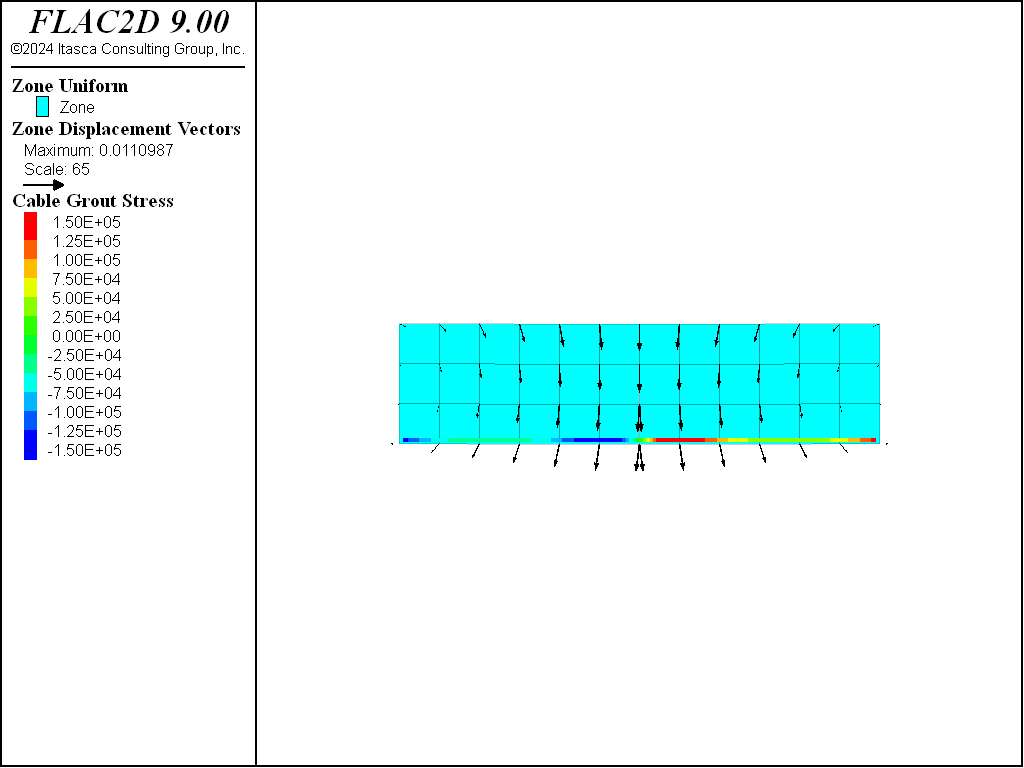

Figure 3: Final grout stress distribution.

The average axial direction of the cable goes from left to right, corresponding with the orientation of the points given with the structure cable create by-line command. In Figure 3, we see that the grout stresses are positive on the right side of the cable and negative on the left side of the cable. These values can be printed with the structure cable list grout command.

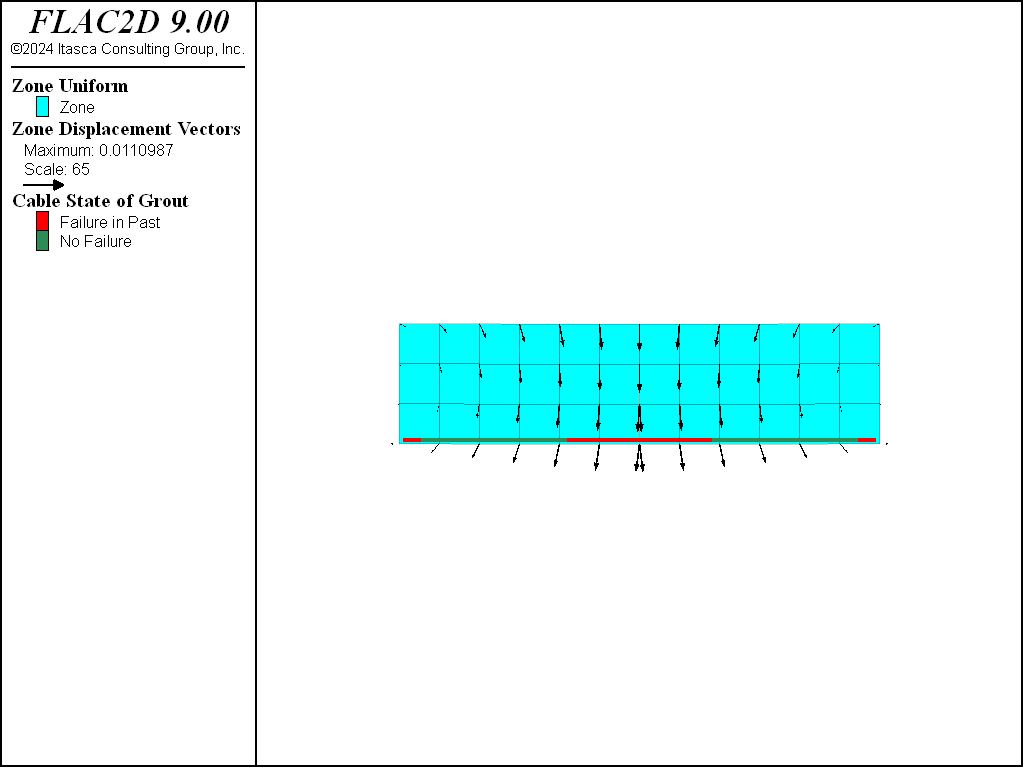

In the previous model, the grout cohesive strength was set to a very large value to prevent grout failure. If we set the grout cohesive strength equal to 1.5 × 105 N/m and rerun the model, we find that the system still stabilizes; however, during the loading process, the grout yields (cable slips) in the middle region (see Figure 4). The grout stress in this region is equal to the grout cohesive strength (see Figure 5), the tensile force is distributed farther along the cable (compare Figure 2 and Figure 6), and the maximum vertical centerline displacement has increased from 9.66 mm to 11.1 mm.

Figure 4: Final grout slip state (reduced grout cohesive strength).

Figure 5: Final grout stress distribution (reduced grout cohesive strength).

Figure 6: Final axial force distribution in cable (reduced grout cohesive strength).

Data File

ReinforcedBeam.dat

model new

model title "Cable-reinforced beam"

; Create beam (composed of zones)

zone create quadrilateral size 12 3

zone face skin ; Label model boundaries

; Create interface betweenthe two

zone interface create by-face separate range position-x 6.0

zone interface node property stiffness-normal 1e10 stiffness-shear 1e10 ...

friction 0

zone interface tolerance-contact 1e-2

; Assign constitutive model and properties

zone cmodel assign elastic

zone property bulk 1e9 shear .3e9

zone initialize density 2400

; Boundary conditions - pin on right and left lower corners

zone gridpoint fix velocity-y 0 range position-y 0 position-x 0

zone gridpoint fix velocity-y 0 range position-y 0 position-x 12

; Setup model

model gravity 10

model large-strain on

model save 'Start'

; Run problem with no cable present

zone mechanical damping combined

model cycle 3000

model save 'NoCable'

; Now rerun problem with a cable present

model restore 'Start'

; Create Cable and set properties

structure cable create by-line (0.1, 0.1) (11.9, 0.1) id=1 segments=13

structure cable property cross-sectional-area=2e-3 young=200e9 ...

yield-tension=1e20 grout-stiffness=1e10 ...

grout-cohesion=1e20 ; 1e11

zone mechanical damping combined

model solve ratio-local 1e-4

model save 'Cable'

; Now allow the cable to fail

structure cable property grout-cohesion 1.5e5

model solve ratio-local 1e-4

model save 'CableFail'

| Was this helpful? ... | Itasca Software © 2024, Itasca | Updated: Nov 12, 2025 |