Heated Specimen with Fixed Boundaries

Note

The project file for this example may be viewed/run in PFC. The data files used are shown at the end of this example.

A temperature increment, \(\Delta T\), is applied to a cubic specimen with constrained boundaries. The surrounding six walls are fixed to constrain the expansion of the specimen, and thermally induced stresses are measured and compared with the analytical values.

Analytical Values

The stress-strain relation with thermally induced strain is given by Equation (1) ([Timoshenko1970a]):

where \(E\) and \(\nu\) are the Young’s modulus and the Poisson’s ratio, respectively. Also, \(\alpha_t\) is the coefficient of linear thermal expansion.

The analytical values for thermally induced stresses on the isotropic specimen are given by Equation (2), substituting \(\sigma_x=\sigma_y=\sigma_z\) and \(\epsilon_x=\epsilon_y=\epsilon_z=0\) into Equation (1):

Model and Results

The file “constrained_expansion.dat” is used for this example. A 2 × 2 × 2 m specimen is created. It comprises approximately 4000 balls with uniform size distribution (radius range from 0.05 to 0.08 m) and a porosity of 0.38. Once the specimen is generated and equilibrated under an isotropic stress state of 100kPa, contact bonds are installed at ball-ball contacts.

The stress and strains are measured using a measurement sphere with a radius of 0.95 m centered within the specimen, and the stresses are also measured on the boundary walls. In PFC, the particle thermal-expansion coefficient is the same as the coefficient of linear thermal expansion: \(\alpha_t\) = 3 × 10-6/°C in this case.

The increment of stress measured at the boundary walls during thermal isotropic constrained expansion are:

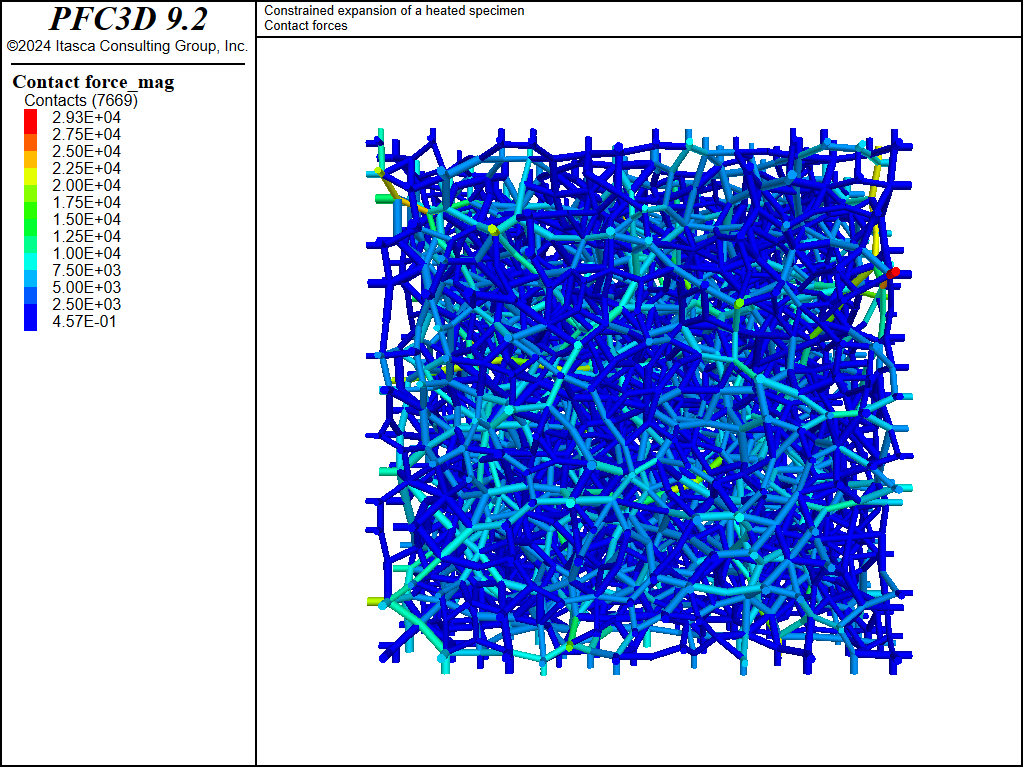

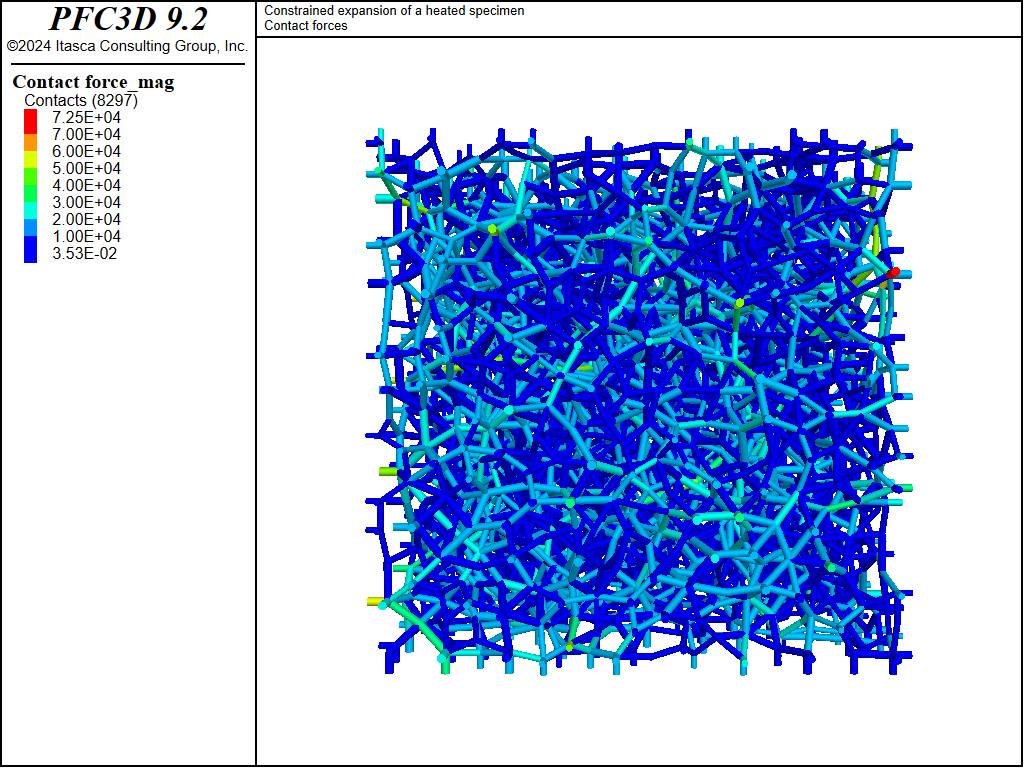

Figures 1 and 2 shows the contact forces colored by magnitude before and after thermal expansion.

Figure 1: Contact forces before thermal isotropic constrained expansion.

Figure 2: Contact forces after thermal isotropic constrained expansion.

To evaluate the analytical solution, the Young’s modulus, \(E\), and the Poisson’s ratio, \(\nu\), are computed by a confined compression test of the specimen at a lateral confinement 100 kPa.

Incorporating these values into Equation (2) leads to:

This value compares well with the measured stress increments reported in (3). The difference may be attributed to the fact that the specimen is not completely uniform; the arbitrary packing produces heterogeneity in the material microstructure.

Reference

Timoshenko, S. P., and J. N. Goodier. Theory of Elasticity, 3rd Ed. New York: McGraw-Hill, 1970.

Data Files

constrained_expansion.dat

; fname: constrained_expansion.dat (3D)

;

; Itasca Consulting Group, Inc.

; ========================================================================

; Thermal option verification problem:

; Constrained expansion of a heated specimen

;

; ========================================================================

program log-file 'constrained_expansion.log'

program log on

; ========================================================================

model new

model large-strain on

model title 'Constrained expansion of a heated specimen'

; -------------------- build specimen ------------------------------------

model domain extent -5 5

contact cmat default model linearcbond ...

method deformability emod 3.0e9 kratio 1.0

wall generate box -1 1

model random 10001

ball distribute resolution 1.0 ...

porosity 0.38 ...

radius 0.05 0.08 ...

box -1 1

ball attribute density 2500.0 damp 0.7

model cycle 2000 calm 100

model mechanical timestep scale

model solve

ball property 'fric' 0.5

ball attribute displacement multiply 0.0

model cycle 1000

model mechanical timestep automatic

model solve

model save 'initial'

; --------------- apply isotropic stress ---------------------------------

model restore 'initial'

program echo off

program call 'triaxial_utils.p3fis'

program echo on

; expand walls

[expand_walls(1.25)]

; install measurement sphere and activate strain calculation

measure create id 1 radius 0.95

[ini_measure]

fish callback add accumulate_mstrains 11.0

; activate wall servo-control

[tsa = -1.0e5]

[tsl = -1.0e5]

[do_zservo = true]

fish callback add servo_walls 1.0

[tol = 5e-3]

[gain_cnt = 0]

[gain_update_freq = 100]

[gain_safety_fac = 0.1]

fish define stop_me

gain_cnt = gain_cnt + 1

if gain_cnt >= gain_update_freq then

compute_gain(gain_safety_fac)

gain_cnt = 0

endif

if math.abs((swxx - tsl)/tsl) > tol

exit

endif

if math.abs((swyy- tsl)/tsl) > tol

exit

endif

if math.abs((swzz - tsa)/tsa) > tol

exit

endif

if mech.solve("ratio-average") > 1e-4

exit

endif

stop_me = 1

end

[wlx0 = wlx]

[wly0 = wly]

[wlz0 = wlz]

[swxx0 = swxx]

[swyy0 = swyy]

[swzz0 = swzz]

[smxx0 = smxx]

[smyy0 = smyy]

[smzz0 = smzz]

fish history emxx

fish history emyy

fish history emzz

fish history ewxx

fish history ewyy

fish history ewzz

fish history smxx

fish history smyy

fish history smzz

fish history swxx

fish history swyy

fish history swzz

model history name "100" mechanical ratio-average

[compute_gain(0.1)]

model solve fish-halt stop_me

; bond active ball-ball contacts

contact method bond gap 0.0 range contact type "ball-ball"

contact property cb_tenf 1e20 cb_shearf 1e20 range contact type "ball-ball"

model save 'iso'

;-------------- estimate Young Modulus and Poisson ratio -----------------

model restore 'iso'

model calm

ball attribute displacement multiply 0.0

[do_zservo = false]

[wlx0 = wlx]

[wly0 = wly]

[wlz0 = wlz]

wall attribute velocity-z 0.0001 range id 1

wall attribute velocity-z -0.0001 range id 2

[gain_cnt = 0]

[compute_gain(0.5)]

[gain_safety_fac = 0.5]

fish define stop_me2

gain_cnt = gain_cnt + 1

if gain_cnt >= gain_update_freq then

compute_gain(gain_safety_fac)

gain_cnt = 0

endif

if ewzz <= -1e-4 then

stop_me2 = 1

endif

end

[ini_measure]

[smxx0 = smxx]

[smyy0 = smyy]

[smzz0 = smzz]

[swxx0 = swxx]

[swyy0 = swyy]

[swzz0 = swzz]

history delete

;set display fish ewzz

model solve fish-halt stop_me2

fish define compute_deformability

local stress = measure.stress(mp)

global ymodm = (smzz - smzz0) / emzz

global pratm = - 0.5*(emxx + emyy) / emzz

;

global ymodw = (swzz - swzz0) / ewzz

global pratw = - 0.5*(ewxx + ewyy) / ewzz

end

[compute_deformability]

model save 'aniso'

;---------------- fix walls and apply +100 deg C -------------------------

model restore 'iso'

fish callback remove servo_walls 1.0

model calm

ball attribute displacement multiply 0.0

wall attribute velocity multiply 0.0

[ini_measure]

[swxx0 = swxx]

[swyy0 = swyy]

[swzz0 = swzz]

[smxx0 = smxx]

[smyy0 = smyy]

[smzz0 = smzz]

history delete

model configure thermal

ball thermal attribute expansion 3.0e-6

ball thermal attribute specific-heat 1.0e3

ball thermal attribute temperature 0.0

ball thermal attribute temperature-increment=100.0

model cycle 1

model thermal off mechanical on

model cycle 1000

model solve

fish define compute_dsig

global dsmxx = smxx - smxx0

global dsmyy = smyy - smyy0

global dsmzz = smzz - smzz0

global dswxx = swxx - swxx0

global dswyy = swyy - swyy0

global dswzz = swzz - swzz0

end

[compute_dsig]

model save 'final'

program log off

program return

; ========================================================================

; eof: constrained_expansion.dat (3D)

| Was this helpful? ... | Itasca Software © 2024, Itasca | Updated: Dec 05, 2024 |