Uniaxial Compression and Extension Tests with Concrete Model

Note

The project file for this example may be viewed/run in 3DEC.[1] The data files used are shown at the end of this example.

In this example to test the Concrete model, a 1 m x 1 m single hexahedral zone is generated, and the material properties are listed in Table 1. The model behavior is compared to laboratory data from Lee and Fenves (1998).

Parameter |

Value |

|---|---|

\(E\) (MPa) |

3.14e4 |

\(\nu\) |

0.18 |

\(f_t^m\) (MPa) |

3.48 |

\(f_t^0\) (MPa) |

3.48 |

\(G_t\) (MN/m) |

40e-6 |

\(l_t\) (m) |

0.0826 |

\(D_t^{half}\) |

0.5 |

\(f_c^m\) (MPa) |

27.6 |

\(f_c^0\) (MPa) |

16.04 |

\(G_c\) (MN/m) |

5690e-6 |

\(l_c\) (m) |

0.0826 |

\(D_c^{peak}\) |

0.4 |

\(f_b^0/f_c^0\) |

1.16 |

\(a_p\) |

0.2 |

\(s_0\) |

0.2 |

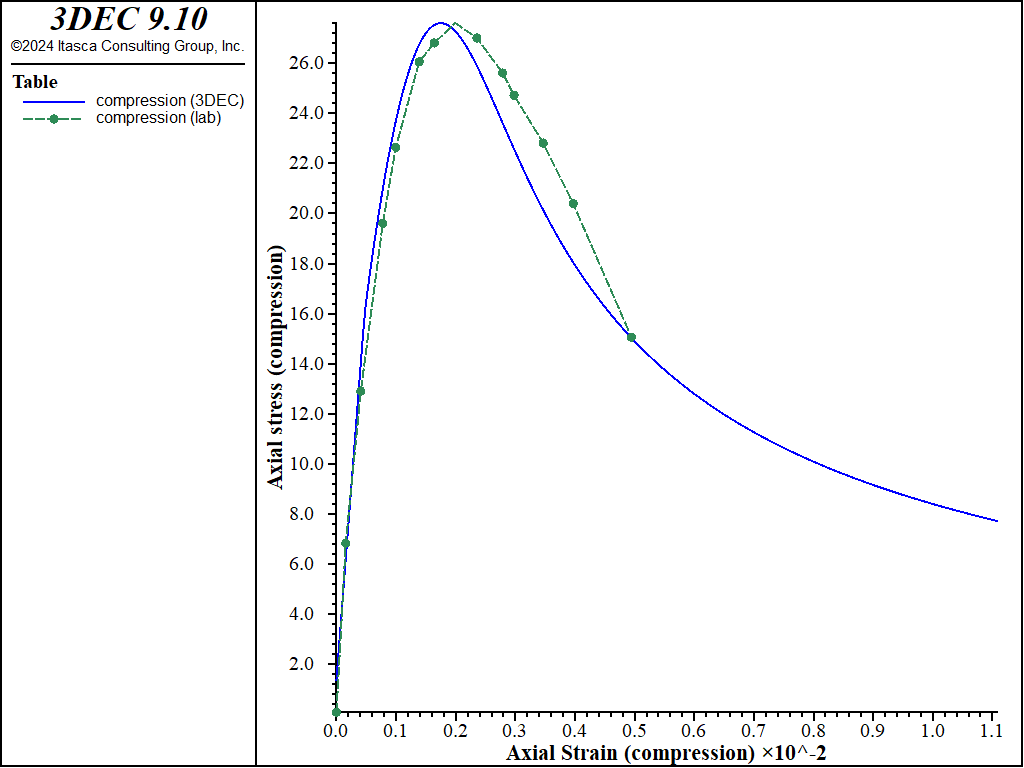

The first test is the uniaxial compression loading. The 3DEC results compared to the laboratory results are shown in Figure 1. The numerical model correctly duplicated the whole loading, which can be verified by the elastic slope (Young’s modulus), initial and peak compression yield stress.

Figure 1: Uniaxial stress vs. uniaxial strain in compression. Compression is positive.

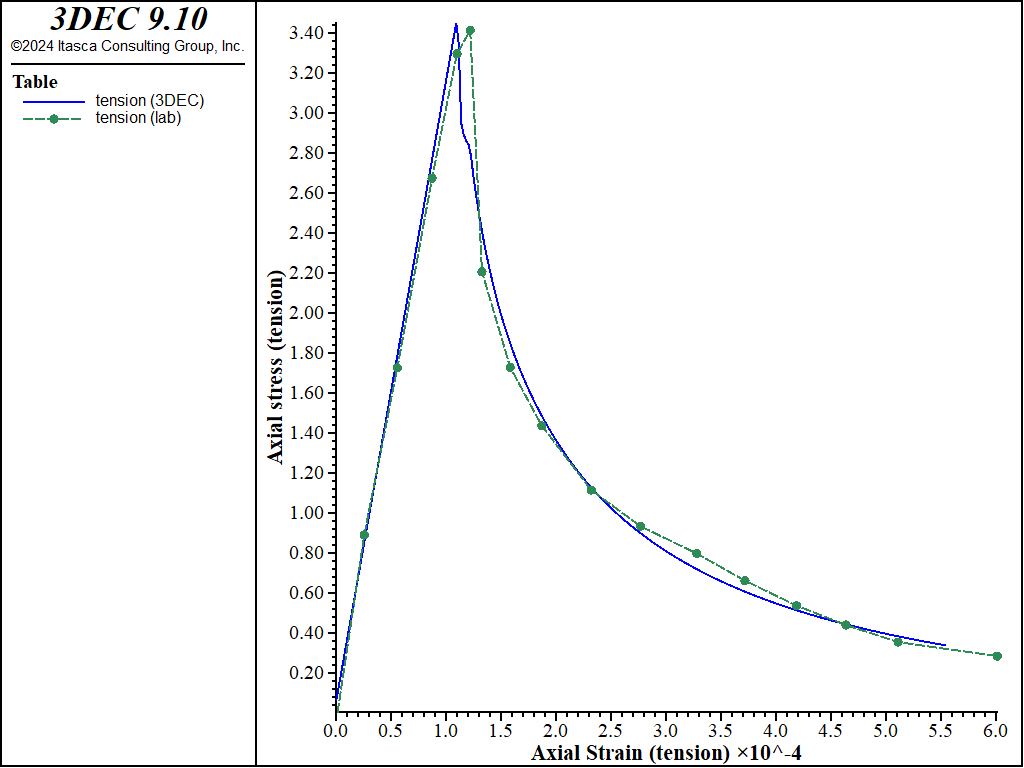

The second test is the uniaxial tension loading. The 3DEC results compared to lab results are shown in Figure 2. Since \(f_t^0=f_t^m\), the uniaxial tension stress vs train curve has immediate softening, which has been correctly simulated by the numerical model the whole loading.

Figure 2: Uniaxial stress vs. uniaxial strain in extension.

References

Lee, J., & Fenvas, G. L. (1998). Plastic-damage model for cyclic loading of concrete structures. Journal of engineering mechanics, 124(8), 892-900.

Data File

uniaxialCompression.dat

model new

model large-strain off

;

fish define parameters

global young = 3.1e4 ; MPa

global poisson = 0.18

global ft = 3.48 ; MPa

global Gt = 40e-6 ; MN/m

global Lt = 0.0826 ; m

global fc = 27.6 ; MPa

global ft = 3.48 ; MPa

global Gc = 5690e-6 ; MN/m

global Lc = 0.0826 ; m

global kbc0 = 1.16

global fc0 = 16.04 ; MPa

global ft0 = 3.48 ; MPa

global dc = 800 ; dc

global dt = 3000 ; dt

end

[parameters]

;

block create brick 0 1

block zone generate hexahedra divisions 1 1 1

;block zone generate-new maximum-edge 0.25

;block zone nodal-mixedip-directionisc on

block gridpoint group 'top' range position-z 1

[global gpsTop = list(block.gp.list)(block.gp.isgroup(::block.gp.list,"top"))]

block zone cmodel assign concrete

block zone property density 2500 young [young] poisson [poisson]

block zone property compression-strength [fc] compression-initial [fc0] ...

compression-energy-fracture [Gc]

block zone property compression-length-reference [Lc] compression-d [dc]

block zone property tension-strength [ft] tension-initial [ft0] ...

tension-energy-fracture [Gt]

block zone property tension-length-reference [Lt] tension-d [dt]

block zone property ratio-biaxial [kbc0] tension-recovery 0.2

block zone property dilation 20

block gridpoint apply velocity-z 0 range position-z 0

[gptr = block.gp.near(1,1,1)]

fish define szz

strain = -block.gp.disp(gptr)->z

szz = -list.sum(block.gp.force.reaction(::gpsTop)->z)

end

history interval 200

fish history name 'strain' strain

fish history name 'szz' szz

block gridpoint apply velocity-z -5e-6 range group 'top'

model step 50000

history export 'szz' vs 'strain' table 'compression-3dec'

table 'compression-3dec' export 'compression-3dec' truncate

model save 'uniaxial-Compression'

uniaxialTension.dat

model new

model large-strain off

;

fish define parameters

global young = 3.1e4 ; MPa

global poisson = 0.18

global ft = 3.48 ; MPa

global Gt = 40e-6 ; MN/m

global Lt = 0.0826 ; m

global fc = 27.6 ; MPa

global ft = 3.48 ; MPa

global Gc = 5690e-6 ; MN/m

global Lc = 0.0826 ; m

global kbc0 = 1.16

global fc0 = 16.04 ; MPa

global ft0 = 3.48 ; MPa

global dc = 800 ; dc

global dt = 3000 ; dt

end

[parameters]

block create brick 0 1

block zone generate hexahedra divisions 1 1 1

;block zone generate-new maximum-edge 0.25

;block zone nodal-mixedip-directionisc on

block gridpoint group 'top' range position-z 1

[global gpsTop = list(block.gp.list)(block.gp.isgroup(::block.gp.list,"top"))]

block zone cmodel assign concrete

block zone property density 2500 young [young] poisson [poisson]

block zone property compression-strength [fc] compression-initial [fc0] ...

compression-energy-fracture [Gc]

block zone property compression-length-reference [Lc] compression-d [dc]

block zone property tension-strength [ft] tension-initial [ft0] ...

tension-energy-fracture [Gt]

block zone property tension-length-reference [Lt] tension-d [dt]

block zone property ratio-biaxial [kbc0] tension-recovery 0.2

block zone property dilation 20

block gridpoint apply velocity-z 0 range position-z 0

[gptr = block.gp.near(1,1,1)]

fish define szz

strain = block.gp.disp(gptr)->z

szz = list.sum(block.gp.force.reaction(::gpsTop)->z)

end

history interval 100

fish history name 'strain' strain

fish history name 'szz' szz

block gridpoint apply velocity-z 5e-7 range group 'top'

model step 25000

history export 'szz' vs 'strain' table 'tension-3dec'

table 'tension-3dec' export 'tension-3dec' truncate

model save 'uniaxial-Tension'

Endnote

| Was this helpful? ... | Itasca Software © 2024, Itasca | Updated: Aug 13, 2024 |