Smooth Square Footing on a Cohesive Frictionless Material

Problem Statement

Note

To view this project in FLAC3D, use the menu command . Choose “VerificationProblems/ SquareFooting” and select “SquareFooting.f3prj” to load. The main data file used is shown at the end of this example. The remaining data files can be found in the project.

This problem is concerned with the numerical determination of the bearing capacity of a smooth rectangular footing on a cohesive frictionless material (Tresca model).

The footing of width 2a and length 2b is located on an elasto-plastic Tresca material with the following properties:

| shear modulus (\(G\)) | 0.1 GPa |

| bulk modulus (\(K\)) | 0.2 GPa |

| cohesion (\(c\)) | 0.1 MPa |

| friction angle (\(\phi\)) | 0° |

| dilation angle (\(\psi\)) | 0° |

Upper- and Lower-Bound Solutions

The problem is truly three-dimensional and, although no exact solution is available, upper and lower bounds for the bearing capacity, \(q\), defined as the average footing pressure at failure, have been derived using limit analysis (see, for example, Chen 1975). The upper bound, \(q^u\), obtained using the failure mechanism of Shield and Drucker (1953), has the form

in which c is the cohesion of the material. The lower bound, \(q^l\), which corresponds to the bearing capacity of a strip footing, has the value

FLAC3D Model

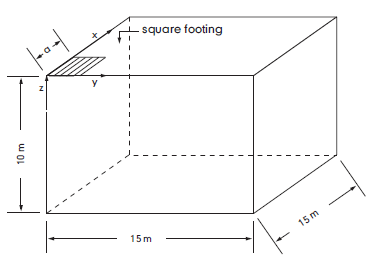

In the numerical example, the footing is square and represented by an area with half-width a (and b = a). Advantage is taken of quarter symmetry, and a parallelepiped domain of 15 m × 15 m × 10 m (as sketched in the figure below) is used in the numerical simulation. The system of coordinate axes is selected with the x- and y-axes in the horizontal plane of the footing, and the \(z\)-axis pointing upward in the vertical direction.

Figure 1: Domain for FLAC3D simulation—quarter symmetry.

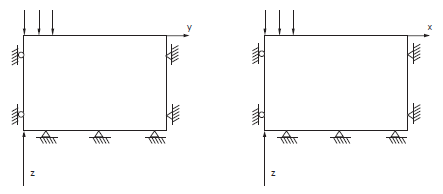

The boundary conditions applied to this domain are sketched below:

Figure 2: Boundary conditions for FLAC3D analysis—quarter symmetry.

The displacements of the far x-, y-, and z-boundaries are restricted in all directions, and the displacements of the symmetry boundaries corresponding to the planes at x = 0 and y = 0 are restricted in the x- and y-directions, respectively. The slab is smooth: displacements are free in the x- and y-directions and a velocity is applied in the negative z-direction to gridpoints within a 3 m × 3 m area to simulate loading of the footing.

The domain is discretized into 1000 zones. The area representing the footing covers a total of 3 × 3 zones. For an applied velocity loading, the bearing area is assumed to extend to half the distance between the last applied gridpoint and the next gridpoint. In this model, then, a = 3.5 m and b = 3.5 m.

The zone dimensions are graded outside the footing area according to a geometrical progression with factor 1.2 in the x-, y-, and z-directions using the Building Blocks pane (see Figure 3). The resulting commands were exported using the State pane into the data file “geometry.f3dat”. A velocity of magnitude 2.5 × 10-5 m/step is applied at the nodes within the footing area for a total of 7500 steps.

The FISH function load found in the file “footing-load.f3dat” computes the normalized average footing pressure, \(p/c\), and the corresponding relative difference with the theoretical normalized upper-bound value, \(q^u/c\) (equation (1) above).

Results and Discussion

The load-displacement curve corresponding to the numerical simulation is presented in Figure 4, in which load is the normalized average footing pressure, p/c; upper and lower are the normalized upper and lower bound value for the bearing capacity, and disp is the normalized vertical displacement, \(u_z/a\), at the center of the footing. The numerical value of the bearing capacity is 526 kPa. This value is sandwiched between the theoretical upper-bound value of 571 kPa and lower-bound value of 514 kPa. The velocity field at the end of the numerical simulation is illustrated in Figure 5.

The same problem was run again using FLAC3D’s nodal mixed discretization (NMD) feature (file “nmd.f3dat”). For this model, an all-tet grid was generating using the file “create-tet-mesh.f3dat”. Figure 6 and Figure 7 show the NMD results and correspond directly with Figure 4 and Figure 5 (results with an all-hex grid). As can be seen, the results are very similar.

References

Chen, W.-F. “Bearing Capacity of Square, Rectangular and Circular Footings,” in Limit Analysis and Soil Plasticity, Developments in Geotechnical Engineering 7, Ch. 7, pp. 295-340, New York: Elsevier Scientific Publishing Co. (1975).

Shield, R. T., and D. C. Drucker. “The Application of Limit Analysis to Punch-Indentation Problems,” J. Appl. Mech., 20, 453-460 (1953).

Data File

;---------------------------------------------------------------------

; Smooth square footing on Tresca material

; -associated plastic flow-

;---------------------------------------------------------------------

model new

model largestrain off

; Initialize parameters

[global a = 3] ; Size of footing in x and y

[global b = 3]

; load building block template geometry.f3dat created interactively

call 'geometry'

; Make footing the size in the parameters, and create zones

building-blocks point move-to x @a range group 'x'

building-blocks point move-to y @b range group 'y'

zone generate from-building-blocks

; Assign constitutive models and properties

zone cmodel assign mohr-coulomb

zone property bulk 2.e8 shear 1.e8 cohesion 1.e5

zone property friction 0. dilation 0. tension 1.e10

; Boundary conditions

zone face apply velocity-normal -2.5e-5 range group 'Footing'

zone face apply velocity-normal 0.0 range position-x 0

zone face apply velocity-normal 0.0 range position-y 0

zone face apply velocity (0,0,0) ...

range union position-x 15 position-y 15 position-z 0

; Call FISH that calculates footing load

call 'footing-load'

; take some histories

history interval 50

fish history @load

fish history @upper

fish history @lower

fish history @disp

model history mechanical ratio-local

; Cycle till velocities stabilize

model cycle 7500

list @lower @load @upper

list @errlo

; Save the model

model save 'sslab'

return

⇐ Smooth Circular Footing on an Associated Mohr-Coulomb Material | Drained and Undrained Triaxial Compression Test on a Cam-Clay Sample ⇒

| Was this helpful? ... | PFC 6.0 © 2019, Itasca | Updated: Nov 19, 2021 |