Uniaxial Compressive Strength of a Jointed Material Sample

Problem Statement

Note

To view this project in FLAC3D, use the menu command . Choose “VerificationProblems/UniaxialStrengthJointed” and select “UniaxialStrengthJointed.f3prj” to load. The main data files used are shown at the end of this example. The remaining data files can be found in the project.

The uniaxial compressive strength of a cylindrical sample of material is evaluated numerically using the ubiquitous-joint model. This model takes into consideration a direction of weakness (ubiquitous-joint) in a Mohr-Coulomb material on which shear failure can be initiated. The compressive strength of the sample is a function of the material and joint properties, as well as the angle, \(\beta\), formed by the direction of the compressive stress and its projection onto the plane of weakness (see Figure 1).

In this example, the sample is selected as a cylinder with radius, a, and height, b, such that \(b/a\) = 4. The Mohr-Coulomb material has the following properties:

| shear modulus (\(G\)) | 70 MPa |

| bulk modulus (\(K\)) | 100 MPa |

| cohesion (\(c\)) | 2 kPa |

| friction angle (\(\phi\)) | 40° |

| dilation angle (\(\psi\)) | 0° |

| tension limit (\(\sigma^t\)) | 2.4 kPa |

The ubiquitous-joint properties include the following:

| cohesion (\(c_j\)) | 2 kPa |

| friction angle (\(\phi_j\)) | 30° |

| dilation angle (\(\psi_j\)) | 0° |

| tension limit (\(\sigma_j^t\)) | 2.4 kPa |

Analytical Prediction

As a definition, let

in which \(\beta\) is the weak-plane angle, as indicated in Figure 1. Before failure occurs, the state of stress is homogeneous in the sample. Failure will be initiated on the weak plane when, for \(\kappa >\) 0,

provided the value \(-\sigma_1\) of the compressive strength (tension positive) does not violate the Mohr-Coulomb failure criterion,

in which

If this criterion is violated, or if \(\kappa \leq\) 0, failure will occur in the matrix instead, on planes inclined at an angle of \((\pi/4 - \phi/2)\) with respect to the axis of symmetry of the sample. See Jaeger and Cook (1979) for details.

FLAC3D Model

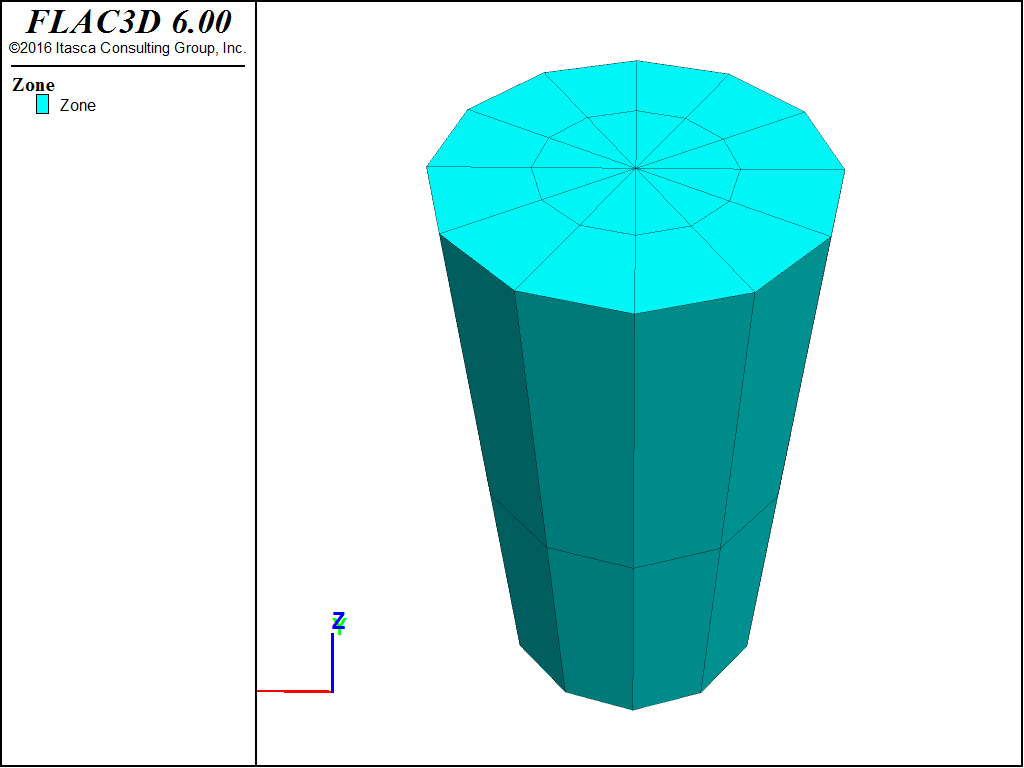

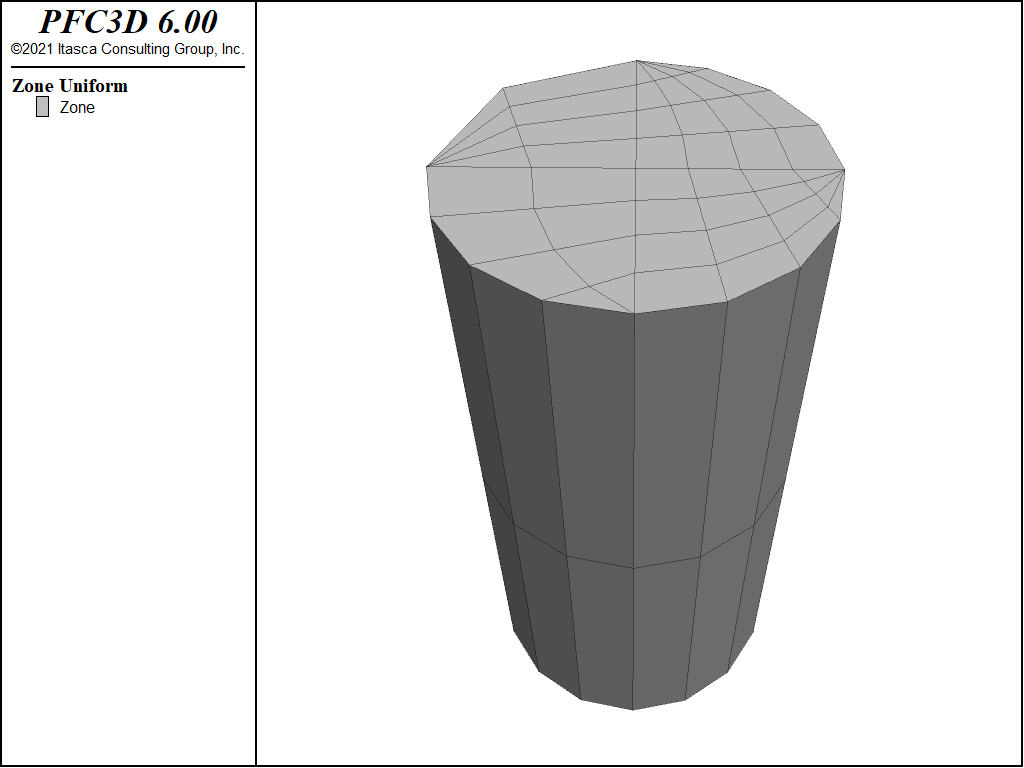

For the numerical simulation, a cylinder with a radius of 1 m and height of 4 m is selected. A system of reference axes with the x- and z-axes located in the base of the cylinder and the y-axis pointing along the cylinder axis is selected. This domain is discretized into 48 zones organized in a radial pattern (see Figure 2). A uniform velocity is applied in the y-direction at both ends of the cylinder to induce compression of the sample.

The effect of the variation of \(\beta\) has been studied every five degrees from 0° to 90°. The

input file uses a FISH function (solveAll) to calculate the compressive strength at each

\(\beta\) value. A zone delete command is issued prior to each calculation at a different

\(\beta\). This deletes all zones to effectively reset the model. The final vertical stress

calculated with FISH function sigmav is added to a table at the end of each run. This approach

allows us to save the whole parametric analysis in one file.

After initiation of the failure mechanism, the state of stress in the sample becomes nonuniform. To better control the deformation of the system, the magnitude of the velocities at the top and bottom of the sample are monitored and adapted as a function of the unbalanced force value (servo-control). The servo keyword used in the zone face apply command controls the magnitude of the applied velocity. Cycling continues until an accumulated displacement of 4.5e-4 is reached (using the FISH function halt), indicating enough total strain to cause failure at all angles.

Results and Discussion

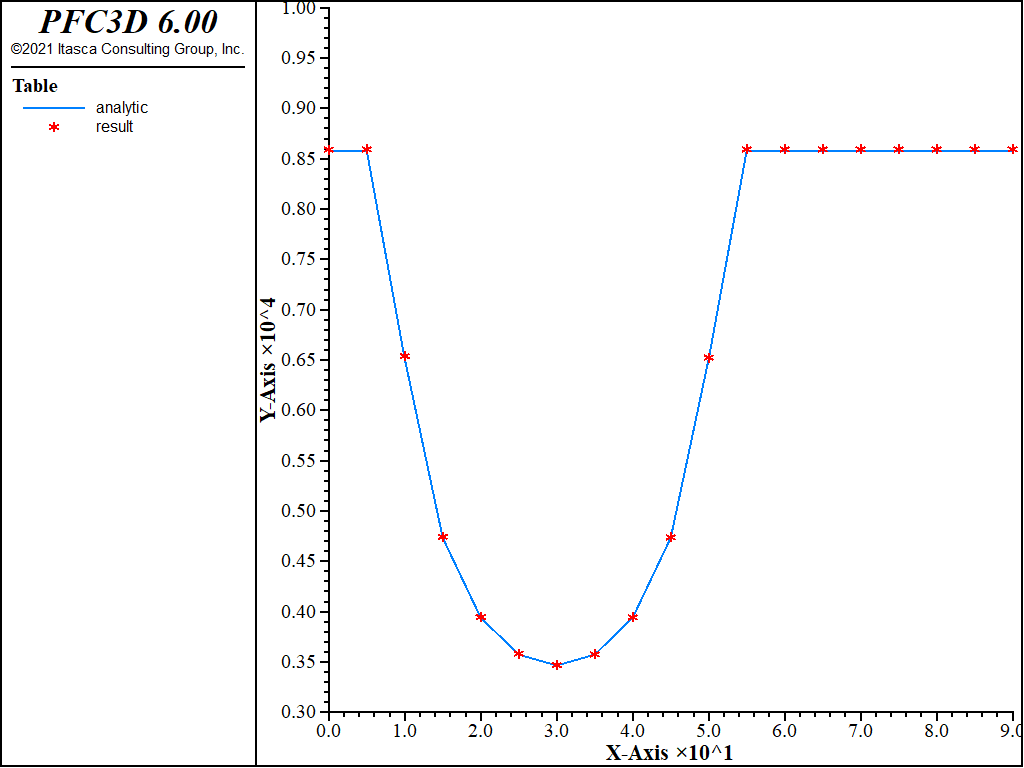

Figure 3 compares results of the FLAC3D runs with the analytical compressive strength predictions. The match is satisfactory, with a relative error smaller than 2% for all values of \(\beta\).

Reference

Jaeger, J. C., and N. G. W. Cook. Fundamentals of Rock Mechanics, 3rd Ed. New York: Chapman and Hall (1979).

Data Files

UniaxialStrengthJointed.f3dat

;---------------------------------------------------------------------

; compression test of cylindrical sample using

; ubiquitous joint model

;---------------------------------------------------------------------

model new

model largestrain off

fish automatic-create off

; Create the Extruder data, generated interactively

; and exported from the State Record

call 'geometry' ; Includes 'top' and 'bottom' group assignments

; Load FISH functions used to support -

; the strength calculation and the halt function

call 'fish-support.f3fis'

; The main function that

fish define solveAll

loop local beta (0,90,5) ; Check angles from 0-90 in 5 degree increments

command

zone delete ; Remove all existing zones

zone generate from-extruder ; Generate new zones from extruder

zone cmodel assign ubiquitous-joint ; Assign model and properties

zone property bulk 1.e8 shea 7.e7 cohesion 2.e3

zone property friction 40. dilation 0. tension 2400.

zone property dip @beta dip-direction 0. joint-cohesion 1.e3

zone property joint-friction 30. joint-dilation 0. ...

joint-tension 2000.

; Assign boundary conditions

zone face apply velocity-normal -5e-7 servo ...

ratio local minimum 1e-4 range group 'Top' or 'Bottom'

; Cycle till the target strain is reached

model solve fish-halt @halt

; Add results to table

table 'result' add (@beta,@sigmav)

end_command

end_loop

end

; Run all 18 cases

@solveAll

; Save the last state, and the accumulated table

model save 'final'

return

fish-support.f3fis

; Function that calculates final strength

fish define sigmav

local sum = 0.

loop foreach local gp gp.list

if gp.isgroup(gp,'bottom') then

sum = sum - gp.force.unbal.y(gp)

endif

endloop

sigmav = sum / 3

end

; Function that determines if solving should stop

fish define halt

global gpHalt = gp.near(0,0,0)

halt = gp.disp.y(gpHalt ) > 4.5e-4

end

| Was this helpful? ... | PFC 6.0 © 2019, Itasca | Updated: Nov 19, 2021 |